18

using threaded fittings in accordance

with the UNI-ISO 7/1 standard. The

use of hemp with suitable adhesives

or Teflon tape as a sealant is allowed.

r© COPPER©PIPE©IN©ACCORDANCE©WITH©THE©

standard, whose joints must be made

using sealed fittings in accordance

with the standard.

r© A©lEXIBLE©STAINLESS©STEEL©SEAMLESS©PIPE©

in accordance with the standard, with

a maximum 2 metre extension and

seals in accordance with the standard.

r© A©lEXIBLE©RUBBER©HOSE©IN©ACCORDANCE©

with the standard, with an 8 mm

diameter for LPG and 13 mm for

natural gas or town gas, maximum

1500 mm in length, firmly secured to

the hose fitting with a safety clamp as

per the standard.

If the gas is supplied directly from

a gas cylinder,

the appliance, fed by a

pressure regulator in accordance with the

standard, must be connected:

r© WITH©A©COPPER©PIPE©IN©ACCORDANCE©

with the standard, whose joints must

be made using sealed fittings in

accordance with the standard.

r© WITH©A©lEXIBLE©STAINLESS©STEEL©SEAMLESS©

pipe in accordance with the standard,

with a maximum 2 metre extension

and seals in accordance with the

standard. We recommend applying

the special adapter to the flexible pipe,

easily found on the market, to facilitate

connection to the pressure regulator’s

hose fitting on the cylinder.

r© WITH©A©lEXIBLE©RUBBER©HOSE©IN©

accordance with the standard, with an

8 mm diameter, minimum 400 mm in

length, maximum 1500 mm in length,

firmly secured to the hose fitting with a

safety clamp as per the standard.

ª !TTENTIONª

If the appliance is going

to be recessed (class 2 subclass 1),

connect it to the gas supply source

using only flexible stainless steel,

seamless pipes in accordance with

the standard.

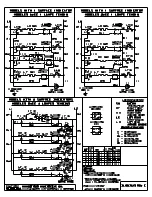

ª !TTENTIONª

If the appliance is going

to be installed free-standing (class

1) and if you use the flexible rubber

hose, it is necessary to follow the

instructions and figures given below

(fig. 20)

ª !TTENTIONª

On its route, the hose

must not touch any parts where the

temperature is more than 95°C.

ª !TTENTIONª

The hose must not be

subject to any kind of torsional

stress or tractive force, there must

be no pinched parts or really sharp

bends.

ª !TTENTIONª

It must not touch

anything that can cut, that has

sharp corners, etc.

ª !TTENTIONª

The whole length of

the hose must be easy to inspect

in order to keep a check on its

condition.

ª !TTENTIONª

It must be replaced

within the date printed on it.

HOT SURFACE

Connection point

Connection point

Hose assembly

Hose

assembly

Isolating tap

Isolating tap

Fig. 20

Содержание 10669GN-MN

Страница 1: ...AEG 10669GN MN COOKER EN User manual ...

Страница 48: ...AEG 10669GN MN 0 123 45 6 78 ...

Страница 49: ...461308493 www aeg com shop ...