Page 9

Single Stage Unitary Range

ES/ESH-LT209_10152019

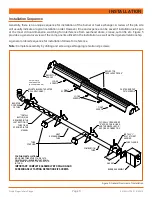

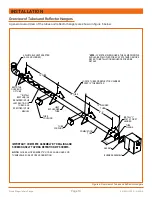

INSTALLATION

Installation Sequence

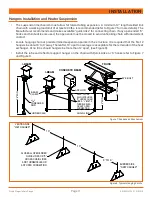

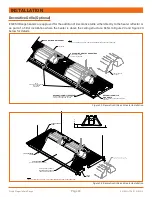

Generally, there is no unique sequence for installation of the burner or heat exchanger. A review of the job site

will usually indicate a logical installation order. However, time and expense can be saved if installation is begun

at the most critical dimension, watching for interference from overhead doors, cranes, auto lifts etc. Figure 5

provides a general overview of the components utilized in the installation, as well as their general relationship.

A general ordered sequence for installation follows for reference.

Note:

Complete assembly by drilling and screwing self-tapping retention zip screws.

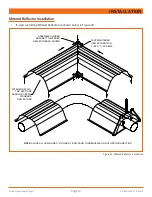

REFLECTOR

OVERLAP APPROX. 8"

REFLECTOR

END CAP

ADJUSTABLE

VENT ADAPTER

(S-20 AND LONGER)

LOOSE

SCREWS

ADJUSTABLE VENT ADAPTER

(S-20 AND LONGER)

TIGHT

FASTEN END CAP

WITH SCREWS

SCREWS

LOOSE

SCREWS

BEND TAB

OVER END

OF TUBE

TIGHT

SCREWS

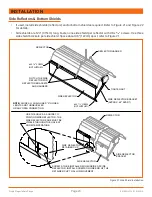

**INSTALL

BAFFLE(S) AS

REQUIRED IN THE

LAST SECTION OF

TUBE OR AS

SPECIFIED IN THE

MANUAL

CLOSE ALL OPEN ENDED

"S" HOOKS, CHAIN LINKS,

AND TURNBUCKLES OR

ANY OPEN CONNECTION.

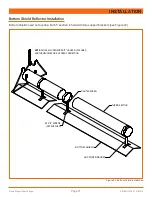

HEAT

INSTALL "J"

EXCHANGER

BOLT AT FIRST

TUBE

HANGER

TUBE

TUBE FLANGE

COUPLING

COMBUSTION

TUBE

COUPLING INSTALLATION

MOVING BETWEEN THE FOUR BOLTS,

TIGHTEN EACH, ENSURING THAT EQUAL

PRESSURE IS APPLIED TO EACH SET PIN

IN TURN.

IMPORTANT: COMPLETE ASSEMBLY BY DRILLING AND

SCREWING SELF TAPPING RETENTION ZIP SCREWS.

GASKET

BURNER ASSEMBLY

3" - 6"

Figure 5: General Overview of Installation