Q2BYG403MD Driver User’s Manual

-13-

Chapter IV. FAQ

4.1 Motor selection

Q2BYG403MD is suitable for 4, 6, 8-wire two phase hybrid step motor.

However, to make the motor have optimized running effect, it is usually

required to select appropriate motor to match the Driver.

(1) It is known from the torque-frequency characteristics of the step

motor that the output torque decreases along with the increase of

motor speed. Generally, at light load, the maximum working speed is

below 15 rev/sec, and at heavy load, the maximum working speed is

about 10 rev/sec. If the system has a higher requirement on speed,

please select servo motor.

(2) If step motor is selected, please select the model of appropriate torque

according to the load.

(3) During working, it is allowed to change the system transmission ratio

through gear box and synchronous belt, and thus adjust the

relationship between output torque and load speed.

(4) Increase the supply voltage of the step motor to improve the working

speed of the motor; increase the working current of the step motor to

improve the torque of the motor; increase the subdivisions of the step

motor to improve the precision of motor, and also improve the

stability of the motor, and reduce vibration and noise.

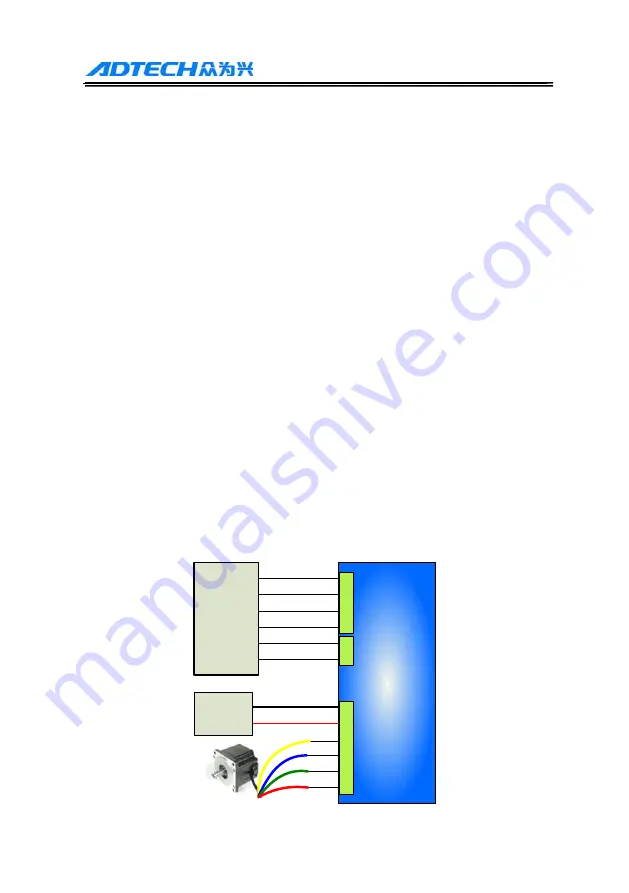

4.2 Typical wiring

The control signal wiring of the controller and Driver can be one of the

three wiring modes shown in 3.3.2. The power supply and motor wiring

is shown below:

Q2BYG403MD

Driver

DR+

DR-

PU-

PU+

EN+

EN-

DC-

DC+

B-

B+

A-

A+

Cotroller

DC power

supply

24-40VDC