EN

8 - MAINTENANCE

Maintenance includes inspections, checks and interventions which, to prevent interruptions and breakdowns,

systematically keep the machine lubrication status and the parts subject to wear under control. These operations,

although simple, must be carried out by Qualified Personnel.

The machine is designed to minimise routine

maintenance. It is the operator’s responsibility to assess the status and its suitability for use. We recommend

stopping the operations and performing maintenance every time operation is not perfect. This will always allow

maximum efficiency.

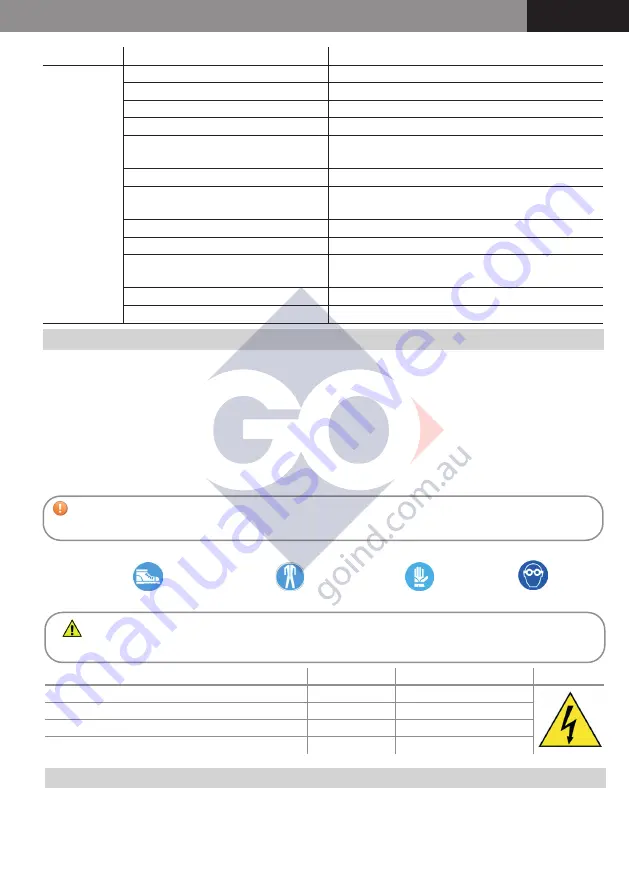

PROBLEM POSSIBLE CAUSE

CORRECTIVE ACTION

LOW OR NO

FLOW RATE

Low level of liquid in the tank

Fill the tank

Filter dirty or clogged

Clean or replace the filter

Foot valve dirty or clogged

Clean or replace the foot valve

Pipe or dispensing nozzle damaged

Replace the damaged components

Excessive negative pressure to the

suction line

Make sure there are no leaks or restrictions on the

suction part (recommended pipes chap. 5.2)

High pressure drops in the circuit

Change the hydraulic discharge configuration

Bypass valve open or blocked

Check the condition of the valve and clean or replace it

if necessary

Vanes blocked

Check and clean the vanes and their housings

Excessive wear of the vanes or impeller Replace the worn components

Leaks from the gaskets

Make sure the gaskets are properly tightened and not

worn

Incorrect power supply voltage

Power the pump as specified on the rating plate

Defective motor

Contact the dealer (fault code M2)

9 - DEMOLITION AND DISPOSAL

If the electric pump is to be scrapped, its parts are to be given to companies specialised in disposing of and recycling industrial

waste, as shown on the table below:

CAUTION! Make sure the pump is disconnected from the power supply and is not in ope-

ration before carrying out any maintenance.

Safety footwear

Protective clothing

Protective gloves

Safety goggles

Always use the appropriate PPE (Personal Protective Equipment):

WARNING! Failure to comply with these requirements will release the manufacturer from any liabi

-

lity resulting from the effects of the Warranty.

MAINTENANCE

FREQUENCY MACHINE STATUS

SYMBOL

Make sure the pipes and couplings are properly connected Every month

Isolation for Maintenance purposes

Check/clean pipes and fittings

Every 12 months

Isolation for Maintenance purposes

Check/clean filter and fittings

Every month

Isolation for Maintenance purposes

Check/clean pump body

Every month

Isolation for Maintenance purposes