06

DESCRIPTION

HeatMaster

©

TC

TECHNICAL

TOTAL CONDENSING: The HeatMaster TC combines the unique ACV Tank-in-Tank concept

with a dual primary circuit resulting in exceptional performance from a totally condensing

combination boiler.

Tank-in-Tank technology

ACV’s advanced implementation of thermal storage technology is tried and tested and is remarkably simple, efficient and reli-

able. At the heart of the HeatMaster TC is a stainless steel tank through which the flue tubes pass. This is surrounded by a mild

steel shell containing the primary water, which extends down to the combustion chamber and even around the flue tubes. The

burner fires onto the primary water which indirectly heats the stainless steel tank containing the hot water. As with all Tank-in-

Tanks, this is corrugated over its full height and is suspended in the HeatMaster TC by its hot and cold water connections. The

area of the heat transfer surface is therefore much greater than that of standard direct fired water heaters. A much larger

heat transfer surface means that Tank-in-Tank units recover much faster than any other kind of hot water

storage device - and keeps boiler cycling to a minimum. The high storage temperature within the inner tank also results in

exceptional hot water outputs.

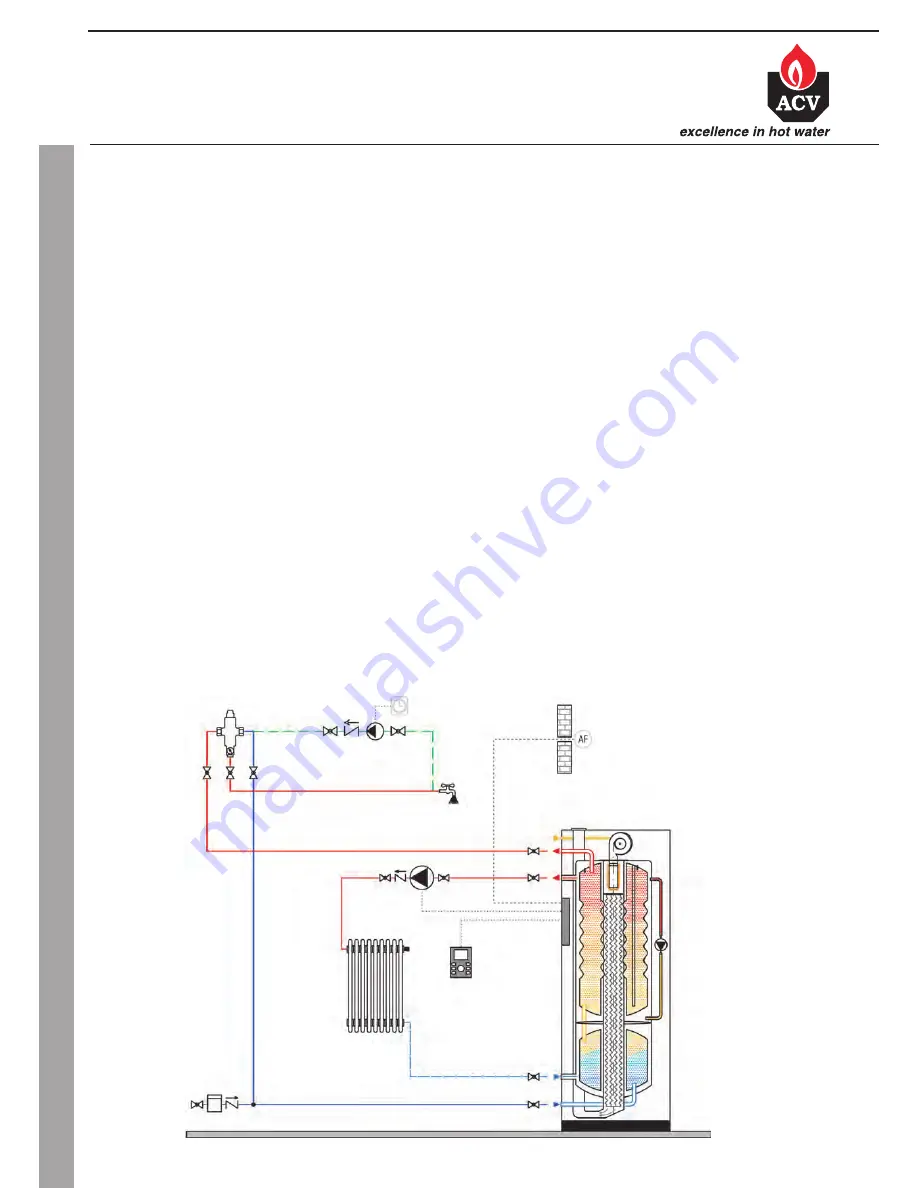

Dual primary circuit technology

The HeatMaster TC primary circuit is split into two sections - a high temperature upper circuit and a low temperature lower

circuit, divided by a separation plate. The hot water storage tank is located in the upper circuit which always operates at a

temperature of between 60°C and 90°C. This is ideal for hot water production as it maintains the stored water at constantly

high temperatures, eliminating bacterial formation such as Legionellae, as well as resulting in high volume hot water produc-

tion. The down-firing flue tubes pass through the upper circuit, through the separation plate and into the lower circuit. The

primary water here operates at a temperature typically between 30°C and 60°C for heating (dependent on the heating return

temperature), perfect for condensing when working in heating mode.

Pre-heating tank technology

During hot water mode, the lower circuit operates at a much reduced temperature, typically 5°C to 20°C depending on the

cold water inlet temperature. The incoming cold water enters the lower primary circuit via a stainless steel tank which pre-

heats the domestic water prior to it passing into the upper stainless steel tank. As the pre-heating tank is wrapped around

the lower flue tubes, it is able to absorb the remaining heat from the flue gases, resulting in a fully condensing HeatMaster TC

during hot water mode either in full or part load conditions.

WORKING PRINCIPLE

cold water inlet

gas

Содержание HeatMaster 35 TC

Страница 1: ...HeatMaster TC TECHNICAL...

Страница 27: ...27 Electric diagram Solar pump DHW circulating pump...

Страница 31: ...31 Electric diagram Mixed HC pump close open...

Страница 33: ...33 Electric diagram Direct HC pump Mixed HC pump close open...

Страница 35: ...35 Electric diagram Direct HC pump Mixed HC pump 1 Mixed HC pump 2 open close open close...