EN • 4

ENGLISH

FRANCAIS

NEDERLANDS

ES

p

A

ño

L

IT

ALIAN

o

DE

u

TSCH

662Y0500 • B

geneRal

energy SaVing

By purchasing this burner, you will be able to make significant

savings in terms of costs, oil and above all, energy!

we recommend that the heating system is regularly inspected

and serviced by a qualified heating engineer in accordance with

DIN 4755.

An indication of the combustion quality and oil consumption can be

obtained by checking the exhaust gas temperature and the burner

running times.

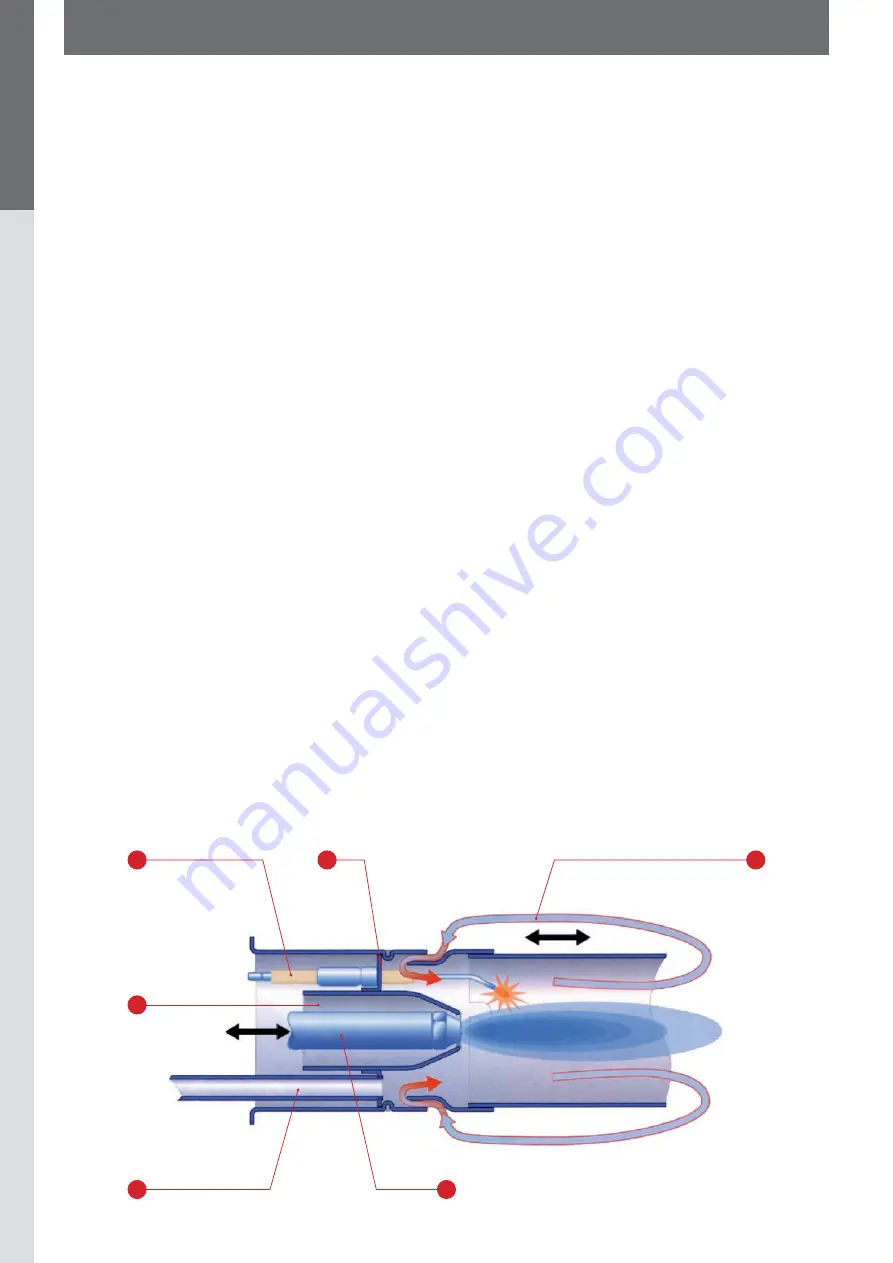

the mixing unit and recirculation

principle

A. Air

B. Ignition electrode

C. Gasket

D. Recirculation

E. Oil

F. Inspection glass for flame detector

the flame makeS the difference

Thanks to many years’ experience of developing blue burners,

we have been able to develop a product that not only meets, but

far exceeds the sophisticated requirements of modern heating

technology. In the design and development phase we took an

innovative route; by combining a new housing with a high-powered

fan which creates a pressure of 9 - 16 mbar behind the nozzle,

we have managed to develop a highly efficient oil gasification

system. This system provides a totally blue flame and an optimum

soot-free burn, whilst running extremely quietly and is a further

step towards green technology.

• Exhaust gas temperature

The exhaust gas temperature is measured using a thermometer

which can be purchased from a specialist shop. The chimney

sweep’s inspection hole is the ideal measuring point. If the exhaust

gas temperature appears to increase by more than 30°C, it

must be assumed that a coating has formed in the combustion

chamber, which will cause the heating system to run inefficiently.

If this occurs, clean the boiler and check the burner immediately.

when comparing with reference measurements, make sure that

the burner running times are the same.

• Operating hours meter

An operating hours meter which records the opening time

of the solenoid valve can be used to monitor oil consumption.

The system is connected to the electrical supply via the B4

terminal of the connection plug.

when comparing with reference measurements, allow for the

respective outside temperature of the year in question.

• Flue gas shut-off valve

Flue gas shut-off valves are occasionally used to prevent excess

cooling during shut-down. when the system is fully shut down,

condensation can form in the boiler and the chimney due to

the interrupted air flow. In addition, hot boiler components may

reflect back onto the nozzle (carbonization). However, the use

of a draught limiter or secondary air device can prevent the

satisfactory ventilation of the chimney and excessive cooling of

the boiler.

F

D

B

C

A

E