7.

CAUTION!

Guards must be installed when fan is within

reach of personnel or within eight (8) feet (2.5 m) of

working level or when deemed advisable for safety.

8. Remove the motor compartment cover (small hood).

CAUTION!

Before proceeding, make sure electrical

service to fan is locked in

“OFF”

position. Run wires

through the internal wiring post to the motor, to disconnect

switch if used.

WARNING!

The wiring post is sealed to the

curb cap with a large washer and sealing gasket. If the

wiring post is loosened, the seal may be broken, thereby

creating a possible water leak.

9. All wiring should be in accordance with local ordinances

and the National Electric Code.

FOR EC Motor Wiring

Go to pages 5 through 11 on how to wire and setup a EC

motor.

10.

WARNING!

Check voltage being supplied to the fan to

see that it corresponds with the motor nameplate voltage;

high or low voltage can seriously damage the motor. On

multi-voltage motors, check motor terminal connections to

make sure motor is internally connected for voltage being

supplied. Motor wiring diagram is located on the side of

the motor or in the motor wiring compartment for ECM

motors go to back of this form for wiring diagrams. Extra

care should be taken when wiring two speed motors since

improper connections will damage motor and void motor

warranty.

11. Apply power momentarily and compare the rotation of

the impeller with the directional arrow on fan.

WHEEL

ROTATION IS CLOCKWISE AS VIEWED FROM TOP

OF FAN.

WARNING!

Operation in the wrong direction

will deliver air but will overload the motor to the extent

of blowing fuses, overload protection and could seriously

damage the motor. In the case of single phase motors, the

reversing instructions will appear on the wiring diagram,

located either in the motor wiring compartment or on the

outside of the motor housing.

12. Using a minimum of eight (8) lag bolts - two (2) on

each side near corners, securely fasten fan to curb,

replace small hood and fasten all bolts securely. The

fan should rest on the curb as level as possible.

Over tightening the bolts can cause the inlet cap to distort

and push the inlet cone into the wheel.

MAINTENANCE

1. Under normal usage, no spare parts are recommended

for one year of operation. Recommended spare parts are

shown on page 4.

2.

CAUTION!

Before proceeding, make sure electrical

service to fan is locked in “OFF” position.

WINDMILLING:

Even when the power is locked out, fans

may cause injury or damage if the impeller is subject to

“windmilling” which is the turning of the impeller and drive

components due to a draft in the system. To guard against

this hazard, the impeller should be secured to physically

restrict rotational movement.

3. Motor bearings are pre-lubricated. Consult information

printed on the motor for lubrication instructions.

4. If motor requires replacement, one comparable to the

original with the same service factor and enclosure must

be used.

SET SCREW TIGHTENING SCHEDULE

1. Before initial operation of the fan, tighten set screws

according to the procedure outlined below.

2. After 500 operating hours or three months, whichever

comes first, tighten set screws to the full recommended

torque.

3. At least once a year, tighten set screws to the full

recommended torque.

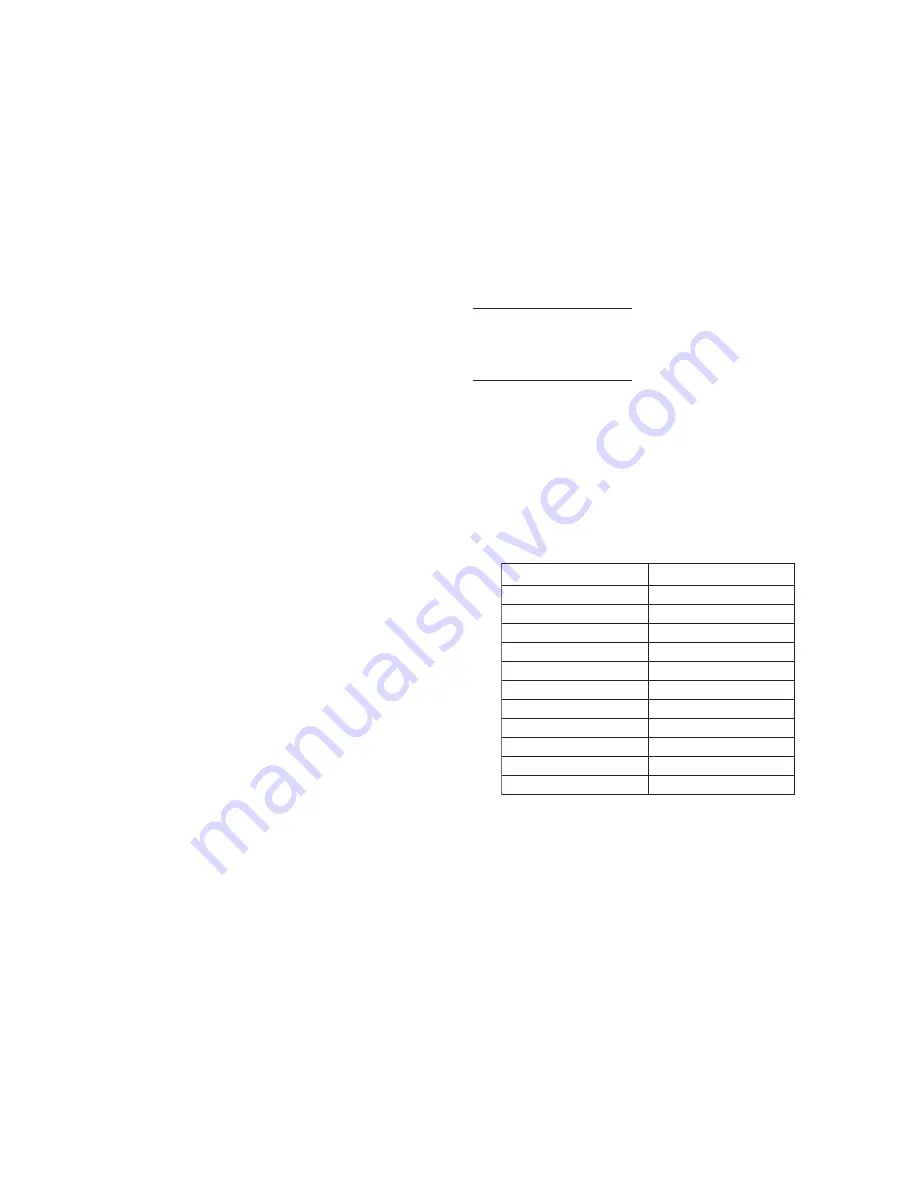

PROCEDURE FOR TIGHTENING SET SCREWS IN

BEARINGS AND HUBS

One Set Screw Application

Using a torque wrench, tighten the set screw to the torque

recommended in Table 1.

Two Set Screw Application

1. Using a torque wrench, tighten one set screw to half of the

torque recommended in Table 1.

2. Tighten the second set screw to the full recommended

torque.

3. Tighten the first set screw to the full recommended torque.

VARIABLE FREQUENCY

DRIVES AND MOTOR

S

There are occasions when a Variable Frequency Drive (VFD)

will cause poor motor performance and possible damage.

To avoid these problems, the Company recommends the

following:

1. Select compatible motor and VFD inverter; if possible,

the motor and the inverter should be from the same

manufacturer or at least the inverter selected should be

recommended by the motor manufacturer.

2. A motor shaft grounding system should be used to prevent

motor bearing damage from eddy currents.

NOTE: The Company will not honor motor warranty claims

if the customer fails to follow these recommendations.

3

Set Screw Diameter

Torque (in-lbs)

#10

35

1/4

80

5/16

126

3/8

240

7/16

384

1/2

744

9/16

1080

5/8

1500

3/4

2580

7/8

3600

1

5400

Table 1. Recommended Tightening Torque

for Set Screws