Application according to designation, general safety instructions

6

Thermal Mass Flowmeter FMT400-VTS, FMT400-VTCS (Sensyflow VT-S/VT-CS)

42/14-36 EN

Notes and

regulations

to be

observed

Observe

– the contents of these operating instructions and references to other documents and their contents

– the safety instructions attached to the mass flow meter

– the application data indicated in the calibration certificate

– the appropriate and valid safety instructions for the construction and operation of electrical systems

– the appropriate and valid safety instructions for handling gases

– the regulations and directives regarding explosion protection.

During

operation

The operator must commission a qualified electrician to inspect and examine the system at defined intervals.

The examination intervals must be chosen in such a way that any damages that can be expected can be recog-

nised in time.

The examinations must be performed at least every three years.

The examinations can be skipped if the electrical system is continuously monitored by a responsible engineer.

Duties of the operator:

– maintain the system in proper condition

– continuously monitor the system

– execute required maintenance and repair work immediately

– carry out required safety measures.

If the devices are used in areas where dusts can cause explosion hazards, you must clean the devices

frequently.

Use genuine spare parts, only.

2.2.2

Notes concerning the use in potentially explosive areas

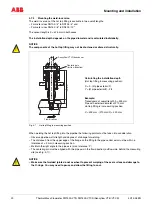

Only FMT400-VTS is available in a version authorized for use in zone 2 / zone 22. These devices come supplied

with an EU declaration of conformity (ATEX). For devices authorized for use in zone 2 / zone 22, only the data

and instructions for use stated in the declaration of conformity (ATEX) shall apply.

DANGER

Using the devices in zone 1 / 21 or in zone 0 / 20 is not allowed.

2.2.3

Notice according to the German Hazardous Material Directive

According to the German Waste Disposal Act dated 1986-08-27 (AbfG. §11 Special Waste) the owner of special

waste is responsible for its disposal. According to the German Hazardous Material Directive dated 1986-10-01

(GefStoffV, §17 General Protection Duties) the employer is also obliged to protect his employees. Therefore, we

must point out the following:

a) All flow sensors and/or flow transducers sent to ABB Automation Products GmbH for repair must be free of

any hazardous substances (acids, lyes, solutions, solids).

b) Flow sensors must be flushed and rinsed in order to neutralize hazardous substances. Flow sensors have

cavities. Therefore, the cavity must be neutralized after operation with hazardous materials (refer to German

Hazardous Material Directive, GefStoffV).

c) In case of service or repair, the measures listed in a) and b) must be confirmed in writing. This signed confir-

mation (return report) must be enclosed with the device whenever a device is returned to the factory.

d) Costs arising from increased efforts for handling of contaminated devices and the disposal of hazardous sub-

stances during repair shall be invoiced to the owner of the device!

!