USER MANUAL

| ICOS | INSTRUCTIONS | UM/ICOS-EN REV. B.2

58

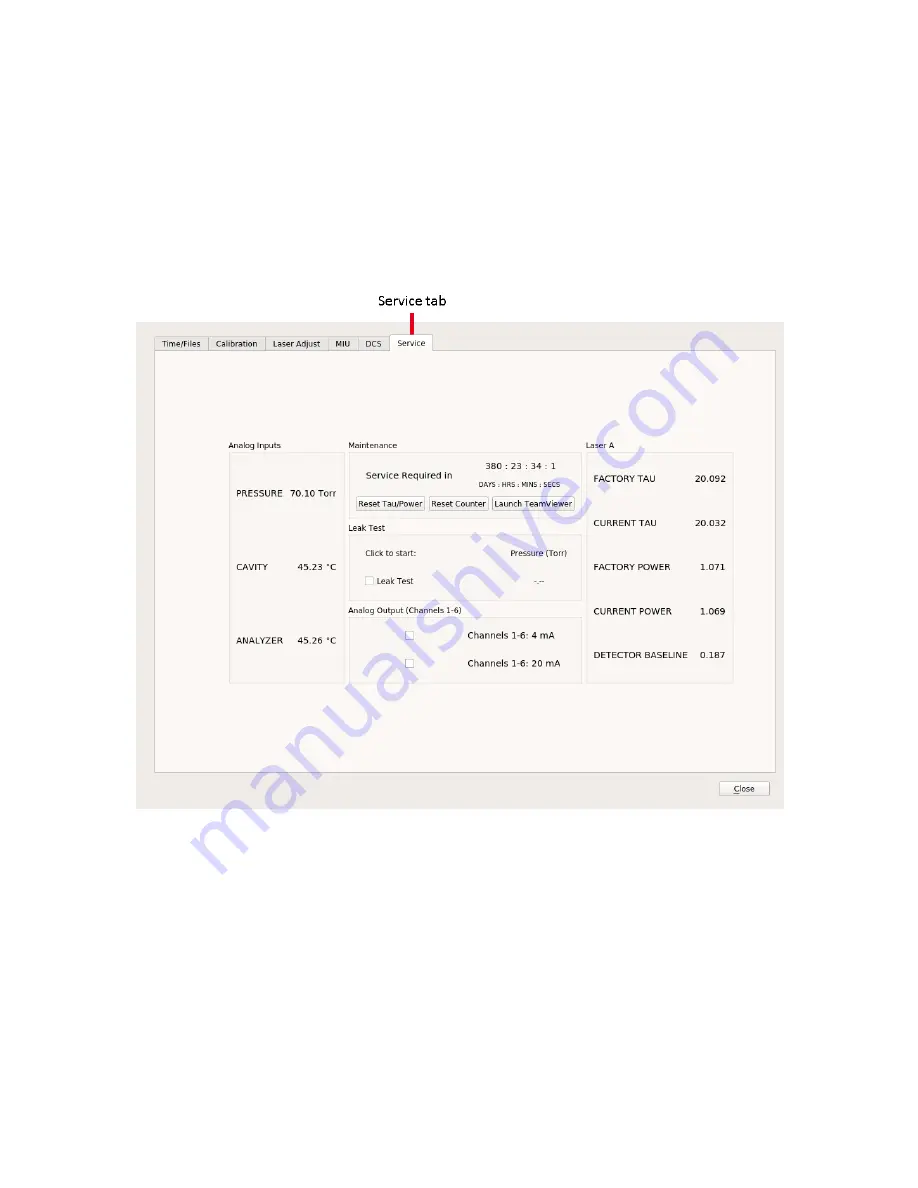

Service

ABB-trained field service engineers monitor the performance of the analyzer via the

Service

screen. (

Figure 43

)

•

These settings determine the level of change that could affect measurement

performance.

•

The alarm threshold levels are analyzer-dependent and are set based upon the last

fixed setting.

Figure 43: Service Screen

The

Service

tab contains 3 Service buttons:

•

Reset Tau/Power

button – resets the mirror ringdown time and laser power to

current settings. This is typically done after mirrors have been cleaned.

•

Reset Counter

button – resets the # of days that maintenance is required. This is

typically done after yearly maintenance.

•

Launch TeamViewer

button – TeamViewer allows service engineers to remotely

access the analyzer if service needs are required.