Operation Manual / TPL73-B.. - 85-B11/ -B12

5 Maintenance / 5.5 Cleaning turbine blades and nozzle ring in opera-

tion

© Copyright 2018 . All rights reserved.

HZTL2480_EN

Revision D

July 2018

5.5 Cleaning turbine blades and nozzle ring in

operation

Combustion of heavy fuel oil in diesel engines causes soiling of the tur-

bine blades and nozzle rings of the turbochargers.

Soiling increases with time, so that regular and properly performed

cleaning is important to remove the accumulated deposits.

The exhaust gas temperature downstream of the cylinders can rise and

the charging pressure at the air receiver can fall if turbine components

become soiled.

A soiled turbine also results in rotor unbalance. Severe soiling can lead to

impermissibly high rotor imbalance.

Experience in operation has shown that despite periodic cleaning during

operation, it is impossible to dispense with overhauls during which the

turbine and nozzle ring are mechanically cleaned. However, if cleaning is

performed correctly and the cleaning system is properly dimensioned,

the intervals between overhauls can be extended.

Wet-cleaning interval

The interval between periodic cleaning is very dependent on the operat-

ing conditions. As a rule, cleaning should be carried out every

50

to

500

operating hours

.

Dry-cleaning interval

The interval between periodic cleaning is very dependent on the operat-

ing conditions. As a rule, cleaning should be carried out every

25

to

50

operating hours

.

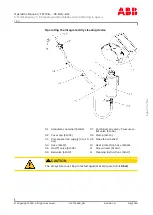

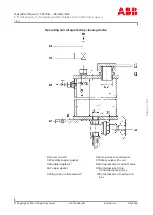

Cleaning methods

Several methods are possible for cleaning the turbine and nozzle ring

during operation. The cleaning methods described in the following have

been tested and are recommended by ABB Turbo Systems:

¡

Wet cleaning

¡

Dry cleaning

Page

67

/

151