2.3

Maintenance

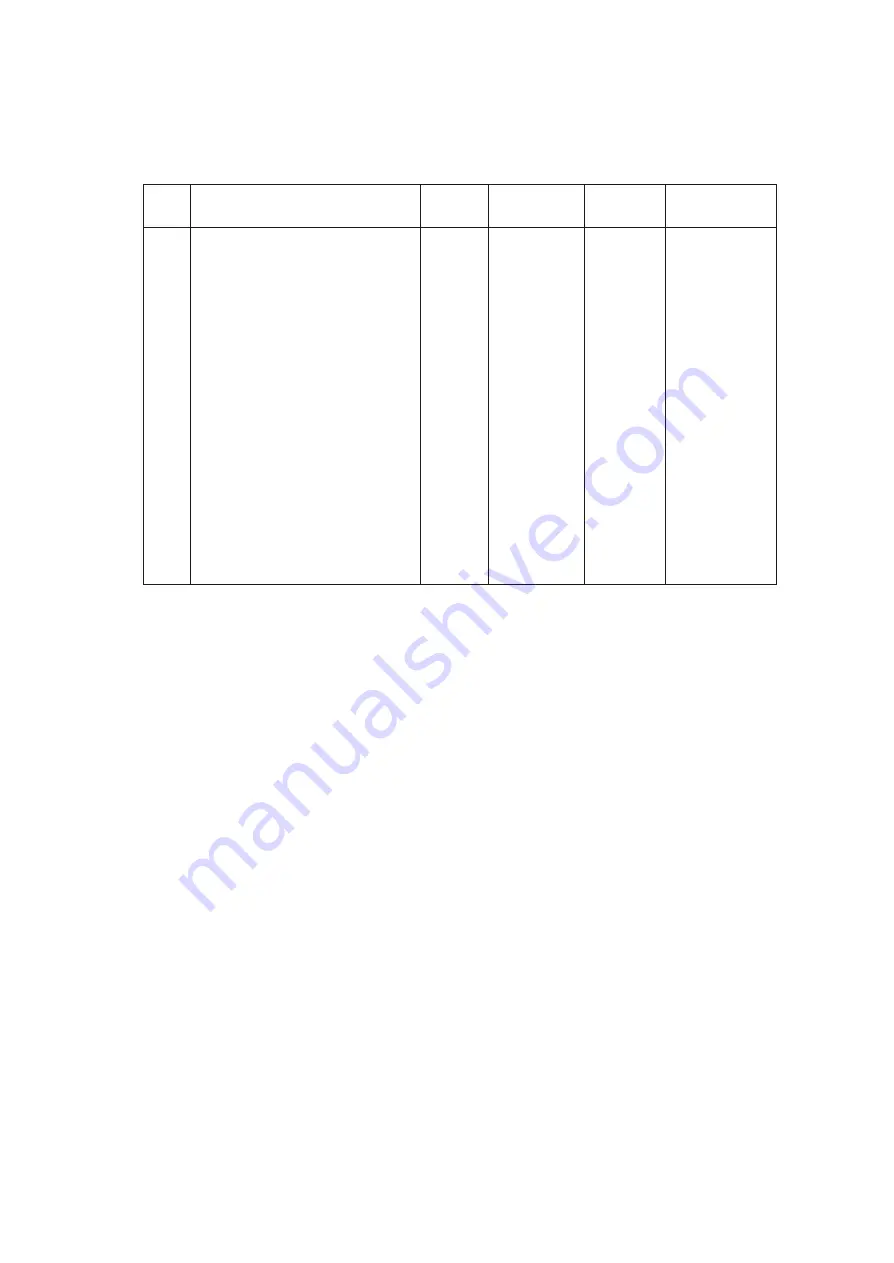

2.3.1 Maintenance schedule (As per Drg. 1VYN400290-005 Pg. 11 & 12)

Sr.

Description

Before Interval

Interval Every

No.

Start up of 6 months of 5 years 1000 operation

01

CHECKING OF OPERATING

MECHANISM.

1.1

Checking of fastener tightness fig. 7A

Item B. H. L. & M.

a

a

----

a

1.2

Checking of shock absorbers for

Leakage or stuck-up fig. 7A item F & G

a

a

----

a

1.3

Checking of top & bottom trip free

mechanism, cap & coupling

Fig. 7A, item J & K

a

a

----

a

1.4

Closing & Tripping spring assembly

& split pin (N) on them (fig. 7A)

----

----

----

a

1.5

Bearing item (P) fig. 7A

----

----

----

a

1.6

Checking of setting

*Coupling and knife catch gap

(Setting 1, fig. 7B)

*Bottom TFM and CAP gap

(Setting 2, fig. 7A) both gaps should

be between 1 - 2 mm

a

a

----

a

1.7

Spring cut off micro switches.

a

a

----

a

02

OVERHAUL & LUBRICATION OF

CHARGING DEVICE AND

OPERATING GEAR

----

----

a

----

03

GAS PRESSURE CHECK

a

a

a

a

NOTE

1) Complete overhaul of circuit breaker with replacement of poles to be done after 10,000 operations.

2) Ask ABB for details of overhaul procedures.

(10)

Содержание HPA 12kV

Страница 7: ...Fig 3b HPA breaker pole for 36 kV ...

Страница 9: ... 7 Fig 5 Circuit Breaker ...

Страница 13: ...Fig 7A Maintenance schedule for frequently operated breaker type HPA 1VYN400290 005 11 ...

Страница 14: ...Fig 7B Maintenance schedule for frequently operated breaker type HPA 1VYN400290 005 12 ...

Страница 15: ...Electrical endurance HPA 13 ...

Страница 29: ......