31

I N SP EC T I O N , M A I N T EN A N C E A N D A DJ US T M EN T

3.

Verify correct operation of the recloser

using the electrical controls.

4.

Perform a hi-pot test to verify the

vacuum integrity.

High voltage applied across an open gap

in a vacuum can produce X-ray radiation.

Radiation note:

When high voltage is applied

across an open gap in a vacuum, X-ray radiation

can be produced. No radiation is emitted when

the recloser is closed because there is no gap.

Additionally, when the recloser is open to the

specified contact spacing during service or testing

within the specified voltages, X-ray radiation at one

meter is below a concerning level. However, there

could be a danger at voltages above or contact

spacing below the specified values on the

nameplate. Follow these steps for the hi-pot test:

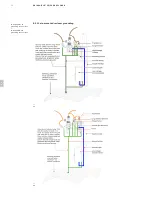

a. With the recloser in the open position,

connect the three top terminals and

the three lateral terminals with jumpers.

Ground the lateral terminals and the

housing. Connect the high voltage source

to the top terminals.

b. Stand more than one meter away before

energizing the high voltage source.

c. Do not exceed 37.5 kV for 15/27 kV or 38 kV

reclosers, and do not apply the voltage for

more than 60 seconds.

Do not use DC voltage for hi-pot testing.

Applying DC voltage for hi-pot testing

is more destructive and, therefore, is not

recommended.

d. If internal flashover occurs, isolate the

phases and test each one independently

to identify the defective interrupter.

Replace any defective pole assembly

before putting the recloser into service.

5.

Measure the contact resistance using suitable

equipment (e.g., micro-ohm meter) rated

at least 100 A DC. The resistance should

not exceed 150 micro-ohms. Measure the

resistance across terminals H1 and H2 when

the contacts are closed.

6.

Measure the actuator coil resistance for each

phase. The coil resistance should not exceed

10 ohms. Refer to table 2 for the correct set

of pins to measure the coil resistance.

—

Table 2: Actuator coil resistance measurement pins

24-pin control 32-pin control

42-pin control

Phase A

Pins 10, 22

Pins Y, Z

Pins 2, 3

Phase B

Pins 9, 21

Pins F, G

Pins 4, 5

Phase C

Pins 8, 20

Pins H, J

Pins 6, 7

7.

Measure the microswitch resistance for the

52a/b contacts. This can be done at the pole

level, on the other end of the control cable

or inside the control cabinet terminal block.

This measurement can also verify continuity.

The measured resistance should not exceed

1.5 ohms. Refer to table 3 to identify the

correct set of pins for measuring microswitch

resistance.

—

Table 3: Microswitch resistance measurement pins

24-pin

control

(52b)

32-pin

control

(52a)

42-pin

control

(52a)

42-pin

control

(52b)

Phase A

Pins 7, 19

Pins F, U

Pins 29, 9

Pins 29, 22

Phase B

Pins 7, 6

Pins F, V

Pins 29, 8

Pins 29, 17

Phase C

Pins 7, 18

Pins F, W

Pins 29, 1

Pins 29, 16

Note: For 24-pin (52b) and 42-pin (52b) measurements,

the recloser needs to be in the open state.

8.

Perform a battery test (if programmed).

Press the PROG1 button on the front of the

RER620. The RER620 will display a “Delta V”

voltage. This value should not exceed 10

percent of the nominal battery voltage (e.g.,

4.8 V for a 48 V battery). A returned value of

99 V for the “Delta V” indicates that the

battery has a very low charge, is disconnected

or has failed. The Delta indication will also

provide a “Pass” or “Fail” message.

For reclosers using the ACM control cabinet,

the battery is continuously monitored by the

Nextys UPS, eliminating the need for periodic

battery testing. If a battery problem arises during

continuous monitoring, an alarm is activated

in the relay.

09

Содержание GridShield 3P

Страница 1: ... DISTRIBUTION SOLUTIONS GridShield 3P 3SP recloser Installation operations and maintenance manual ...

Страница 2: ......

Страница 4: ... GridShield 3P 3SP recloser ...

Страница 27: ...27 INSTALL ATION 8 2 2 Substation mount recloser grounding 36 GridShield 3P substation mount grounding 36 0 8 ...

Страница 39: ...IMPORTANT SAFET Y NOTES AND WARNINGS 39 ...