Description

Routine

Returns allowed number of details to stack on outbelt

FUNC num getAllowed-

NumberToStack()

Add current branch to validated array.

PROC ValidateLight-

Branch()

Standardized sequences are used to load and unload details in the machine, using

the detail data from FlexLoader Vision. These sequences must be checked prior

to each commissioning.

The sequences are based on the machine being loaded from the front. If the

machine is loaded from above or if anything else is unusual, some adjustments

are required.

•

LoadMachine_MAIN

•

LoadMachine_MAIN_UnLoad_SUB

•

LoadMachine_SUB

•

LoadMachine_SUB_UnLoad_MAIN

•

UnLoadMachine_MAIN

•

UnLoadMachine_SUB

•

UnloadMachine_MAIN_Load_MAIN

•

UnloadMachine_SUB_Load_SUB

•

UnloadMachine_LeftOverPart_MAIN

•

UnloadMachine_LeftOverPart_SUB

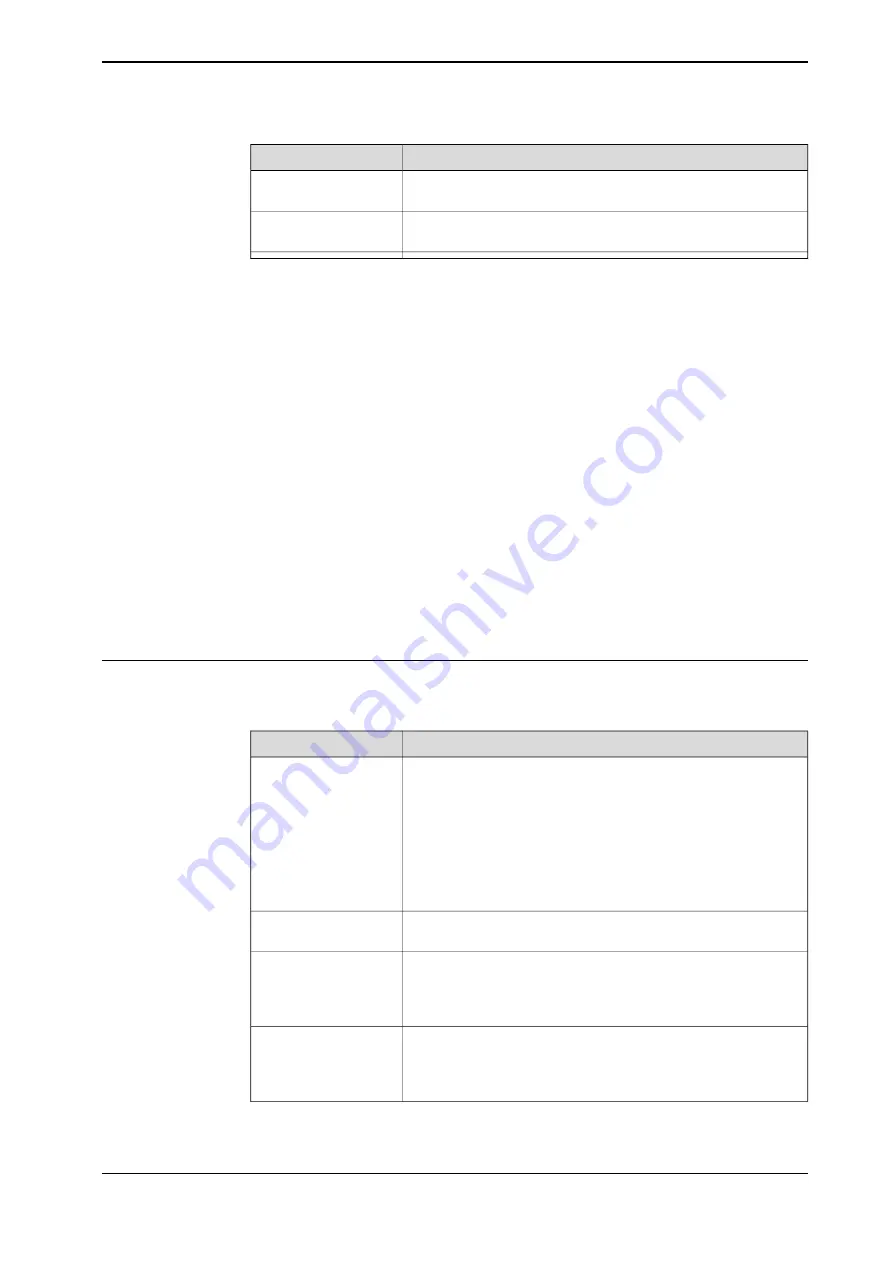

FeederOut.sys

The module FeederOut.sys provides routines for control of outconveyor and leave

pattern calculation.

Description

Routine

This procedure is called from user program whenever a detail

should be placed on outconveyor.

FUNC pos CalcFeed-

erOutLeaveOffset(\inout

num presentLayer,\num

feederNo,\bool leftOver-

Part)

User should use the returned offsets for the leave position when

leaving detail and then call ConfirmLeaveFeederOut when finished.

If no confirm, then robot will get the same leave offsets next time

this function is called.

If using SetUpFeederOutBelt the leave position pLeaveFeederOut

is forced to x,y,z = 0,0,0 in this function! Never change that position

name.

Help procedure for calibrating out belt speed

PROC CalibSpeedFeed-

erOut()

Call this to confirm that last detail has been placed at the last co-

ordinates that was given from CalcFeederOutLeaveOffset.

PROC ConfirmLeave-

FeederOut(\num feed-

erNo)

Number of parts left at feeder out is updated and belt is started if

current row is full.

This function checks if robot has permission to leave on feeder

out.

FUNC bool hasPermis-

sionToLeaveFeed-

erOut(\num feederNo)

If selected, it will also check if feeder out has moved and in that

case re-initialize the feeder.

Continues on next page

Product manual - FlexLoader Vision

273

3HAC051771-001 Revision: B

© Copyright 2014-2018 ABB. All rights reserved.

B FlexLoader RAPID reference

B.4 FlexLoader Vision Lite functionality

Continued

Содержание FlexLoader Vision

Страница 1: ...ROBOTICS Product manual FlexLoader Vision ...

Страница 8: ...This page is intentionally left blank ...

Страница 12: ...This page is intentionally left blank ...

Страница 14: ...This page is intentionally left blank ...

Страница 16: ...This page is intentionally left blank ...

Страница 62: ...This page is intentionally left blank ...

Страница 96: ...This page is intentionally left blank ...

Страница 180: ...This page is intentionally left blank ...

Страница 218: ...This page is intentionally left blank ...

Страница 286: ......

Страница 287: ......