Trouble

shooting

OI/PME/LME/EAN823/EBN853/EBN861-EN

37

8 Trouble

shooting

This chapter only covers hardware-related errors. For additional troubleshooting information, refer to the online

help for the operator interface.

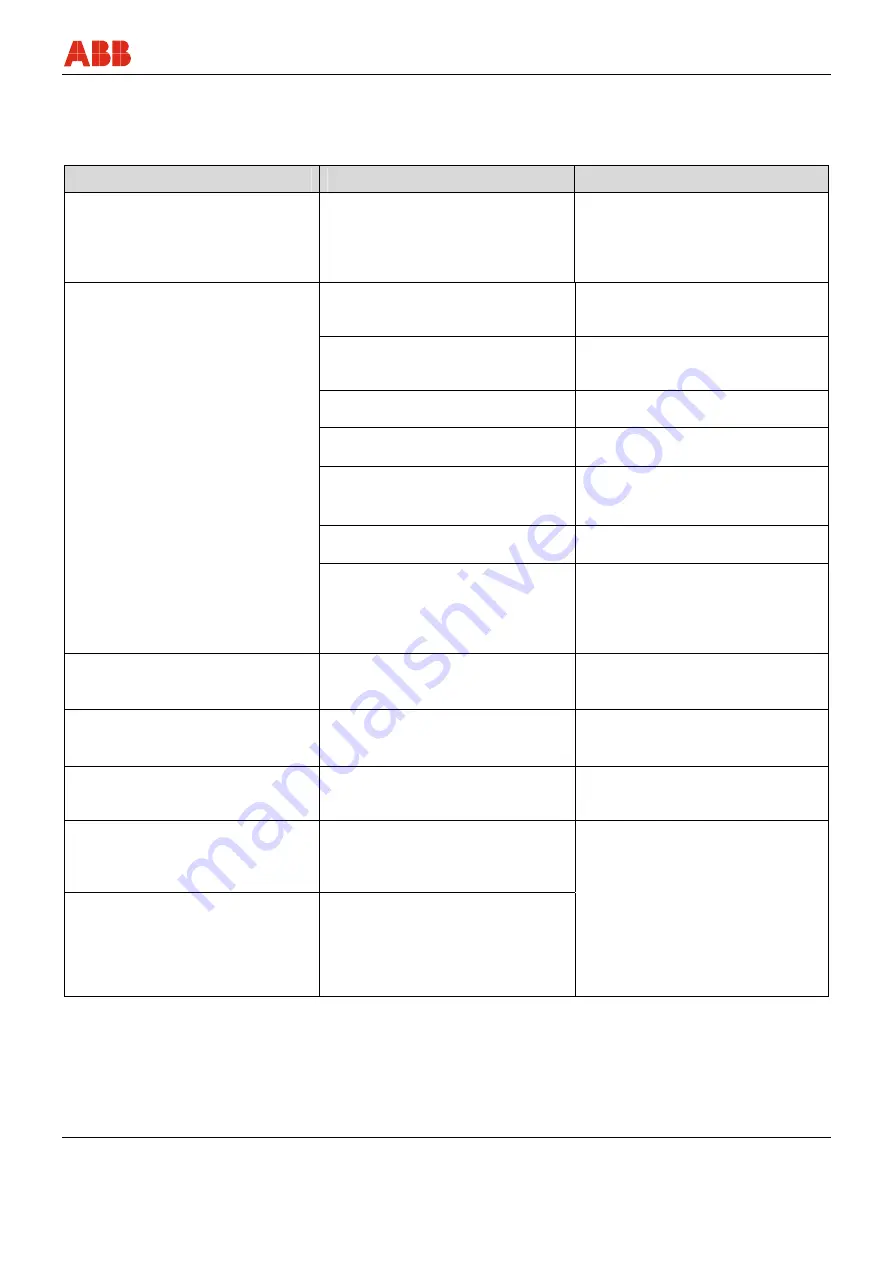

Error

Possible cause

Troubleshooting

Valve cannot be moved by actuator.

Failure either on the actuator or the

valve (e.g., stuffing box tightened

too much).

Disconnect actuator from valve.

If the actuator moves, the valve is

the possible cause.

If the actuator does not move, the

actuator is the possible cause.

Incorrect electronic unit or incorrect

data record.

Compare information on name

plates for actuator and electronic

unit.

Incorrectly configured electronic

unit.

Check / change. Change the

settings via the parameterization

software.

No communication with the control

system.

Check wiring.

Incorrect wiring between actuator

and electronic unit.

Check wiring.

Defective motor/brake.

Check the winding resistance of the

motor and brake.

Check the brake lock.

Binary inputs on the electronic unit

are not wired.

Make connection.

The actuator does not respond.

Brake does not release (no

mechanical "click").

Check the brake air gap (approx.

0.25 mm (0.010 inch)) and

electrical connection to the brake.

Check winding resistance of the

brake coil.

Actuator does not run in AUT mode,

although “AUT” is selected in the

user interface.

Digital input 1 (DI 1) not wired.

Make connection.

Check the software settings for the

digital inputs.

Actuator does not respond to control

(LED 5 flashing at 1 Hz) (software

version 2.00 and higher).

Actuator to manual mode (MAN) via

ISF.

Switch actuator to automatic mode

(AUT).

LEDs in the commissioning and

service panel (ISF) are flashing

synchronously.

Actuator is not adjusted properly.

Adjust actuator.

LEDs flash alternately.

Electronic unit / drive malfunction.

Malfunction when approaching the

end position.

Actuator in limit range of positioning

sensor.

Drive the actuator beyond the

adjusted end position, either

manually or using the buttons on the

ISF; (if necessary disconnect from

valve before)

Drive the actuator back into the

operating range and connect it to the

valve.

Readjust the actuator for the

operating range.