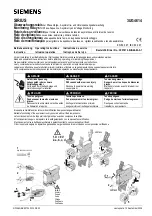

Tamper-Resistant Full-Load Current

Cover

Adjustment Dial

Protection Class

S itch

Remote Reset

0

Current Transformer

Trip Indicator &Manual

Trip Test Lever

(shown in ON position)

Terminals (bottom)

Figure 2. Top face of Solid State Overload Relay, with controls and

features indicated.

Adjusting the Solid State Overload

Relay

The following adjustments to the Solid State Overload

Relay are illustrated in Figure 2. The adjustments

should be performed in the following order.

The settings as the unit is received from the factory

are as follows:

• Full-load current at minimum.

• Protection class at 20.

Full-Load Current Adjustment

This setting is the current beyond which the Solid

State Overload Relay will trip. Use the following

guidelines to determine the appropriate setting:

• For motors with a service factor of 1.0, set the full

load current on the Solid State Overload Relay to

0.9 times the full-load amps (FLA) rating on the

motor's nameplate.

• For motors with a service factor of 1.15-1.25, set

the full-load current on the Solid State Overload

Relay to the FLA rating on the motor's

nameplate.

Press on the tamper-resistant cover above the FLA dial,

then lift up near the tab on the other side to remove

the cover. Rotate the FLA dial so that the arrow on the

dial points to the desired current, as indicated by the

ampere markings around the dial. Do not rotate past

the marked area. The knob moves in small steps to

allow precise adjustment of the full-load current.

Replace the tamper-resistant cover to provide addi-

tional dust protection. To protect against unauthorized

persons' tampering with the settings, insert a wire

lock through the locking tabs.

Phase Loss Sensitivity

The Solid State Overload Relay contains a trip function

activated by a phase loss. This protection is activated when

one phase loses current and either one of the remaining

phase currents exceeds 95% of the minimum FLA of the

Overload Relay. A phase loss trip occurs within 3-6 seconds

of loss of phase current.

Protection Class Setting

CAUTION:

The slide switch must be in one of the

three detent positions. If the slide is between one of

the detents, the default is protection class 30.

AITENTION:

Le bouton de selection de la classe de

protection doit etre dans une des trois positions stables.

Si le bouton se trouve entre deux positions, la classe de

protection est fixee a 30 par default.

Set the desired protection class to 10, 20, or 30 by

sliding the switch to the appropriate detent position.

The time-current curves for the protection classes are

shown in Figure 3. Select the class appropriate to the

particular application.

1000

iii

,:,

C

¥

100

�

E

j::

Cl)

C

·a

� 10

I,.

,'\.

��

�

-

.....

-

-

..__

"""""

........

---

-....i,,...

1--......

...............

1-..............

--

...

r---,......

-..............,

--

..........

r-

r--

r-,...

-

Class 30

Class 20

Class 10

2

3

4

5

6 7 8 9 10

Multiples of Full Load Amps setting

Figure 3. Time-current curves (cold state) for the protection classes.

Test

for Welded Contacts

The following

procedure can be

performed

periodically to insure that the Solid State Overload

Relay contacts have not welded because of a short

circuit in the control circuit.

1. Disconnect all power and control wiring from

the Solid State Overload Relay.

2. Place a bell set or resistance-measuring

instrument across the NC relay terminals (95

and 96).

Содержание CR324GXNS

Страница 3: ......