41-337.31 C

5

4.4.

Setting Calculations

No calculations are required to set the CA-16.

4.5.

Setting The Relay

No settings are required on the CA-16 relay.

5.0

INSTALLATION

The relays should be mounted on switchboard panels

or their equivalent in a location free from dirt, moisture,

excessive vibration and heat. Mount the relay verti-

cally by means of the four mounting holes on the

flange for the semi-flush type FT case. The mounting

screws may be utilized for grounding the relay. Exter-

nal toothed washers are provided for use in the loca-

tions shown on the outline and drilling plan to facilitate

making a good electrical connection between the relay

case, its mounting screws and the relay panel. Ground

Wires are affixed to the mounting screws as required

for poorly grounded or insulating panels. Other electri-

cal connections may be made directly to the terminals

by means of screws for steel panel mounting.

For detail information on the FT case refer to IL 41-

076 for semi-flush mounting.

6.0

ADJUSTMENTS AND MAINTENANCE

The proper adjustments to insure correct operation of

this relay have been made at the factory. Upon

receipt of the relay, no customer adjustments should

be required.

6.1.

Acceptance Check

The following check is recommended to insure that

the relay is in proper working order. The relay should

be connected per Figure 8.

A.

Minimum Trip Current

Apply current to terminals 12 and 13 of the relay. The

relay should operate as follows:

CA-16

0.15 amperes

±

5%

B.

Percentage Differential Characteristic

Apply 16 amperes to terminals 9 and 19 of the CA-16

relay. The contacts should close when the following

operating current is applied to the relay with connec-

tions of Figure 8.

CA-16

17.0 amperes

±

7%

Check each individual restraint winding by applying

50 amperes to each winding. Apply sufficient operat-

ing current to the operating circuit until the contacts

just close. The operating current should be:

CA-16

3.9 to 5.1 amperes

C.

Time Curve

Apply 20 amperes to terminals 12 and 13 of the

relays. The contacts should close in the following

times:

CA-16

58 to 68 Milliseconds

D.

Indicating Contactor Switch (ICS)

Close the main relay contacts and pass sufficient dc

current through the trip circuit to close the contacts of

the ICS. This value of current should not be greater

than the particular ICS nameplate rating. The indica-

tor target should drop freely.

Repeat above except pass 85% of ICS nameplate

rating current. Contacts should not pickup and target

should not drop.

E.

Sensitive Fault Detector

Apply current to terminals 14 and 15 of the relay. The

fault detector should operate between the limits of

0.142 to 0.158 amperes.

6.2.

Routine Maintenance

All contacts should be periodically cleaned. A contact

burnisher is recommended for this purpose.

(S#182A836H01). The use of abrasive material for

cleaning contacts is not recommended, because of

the danger of embedding small particles in the face

of the soft silver and thus impairing the contact.

7.0

CALIBRATION

Use the following procedure for calibrating the relay if

the relay has been taken apart for repairs or the

adjustments disturbed. This procedure should not be

used until it is apparent that the relay is not in proper

working order. (See “Acceptance Check”.)

7.1.

Contacts

Adjust the adjustable stop screw on the upper disc of

the relay so that a contact separation of 0.050 inch is

obtained between the moving contact and the sta-

tionary contact. Lock the screw with the nut provided

for the purpose.

7.2.

Minimum Trip

The relay should be level for this test. Minimum trip

Содержание CA-16

Страница 1: ......

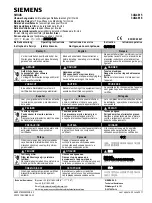

Страница 2: ...41 337 31 C 2 Figure 1 CA 16 Front View Figure 2 CA 16 Rear View ...

Страница 7: ...41 337 31 C 7 Figure 3 Internal Schematic of the Type CA 16 Bus Relay Sub 1 3532A95 ...

Страница 8: ...41 337 31 C 8 Figure 4 Typical Time Curves of the CA 16 Differential Relay Sub 1 537956 ...

Страница 12: ...41 337 31 C 12 Figure 8 Diagram of Test Connections for the CA 16 Relay Sub 4 187A426 ...

Страница 13: ...41 337 31 C 13 Figure 9 Percentage Slope Curve of the CA 16 Relay with One Restraint Winding Sub 1 849A450 ...

Страница 15: ......