Fieldbus control

274

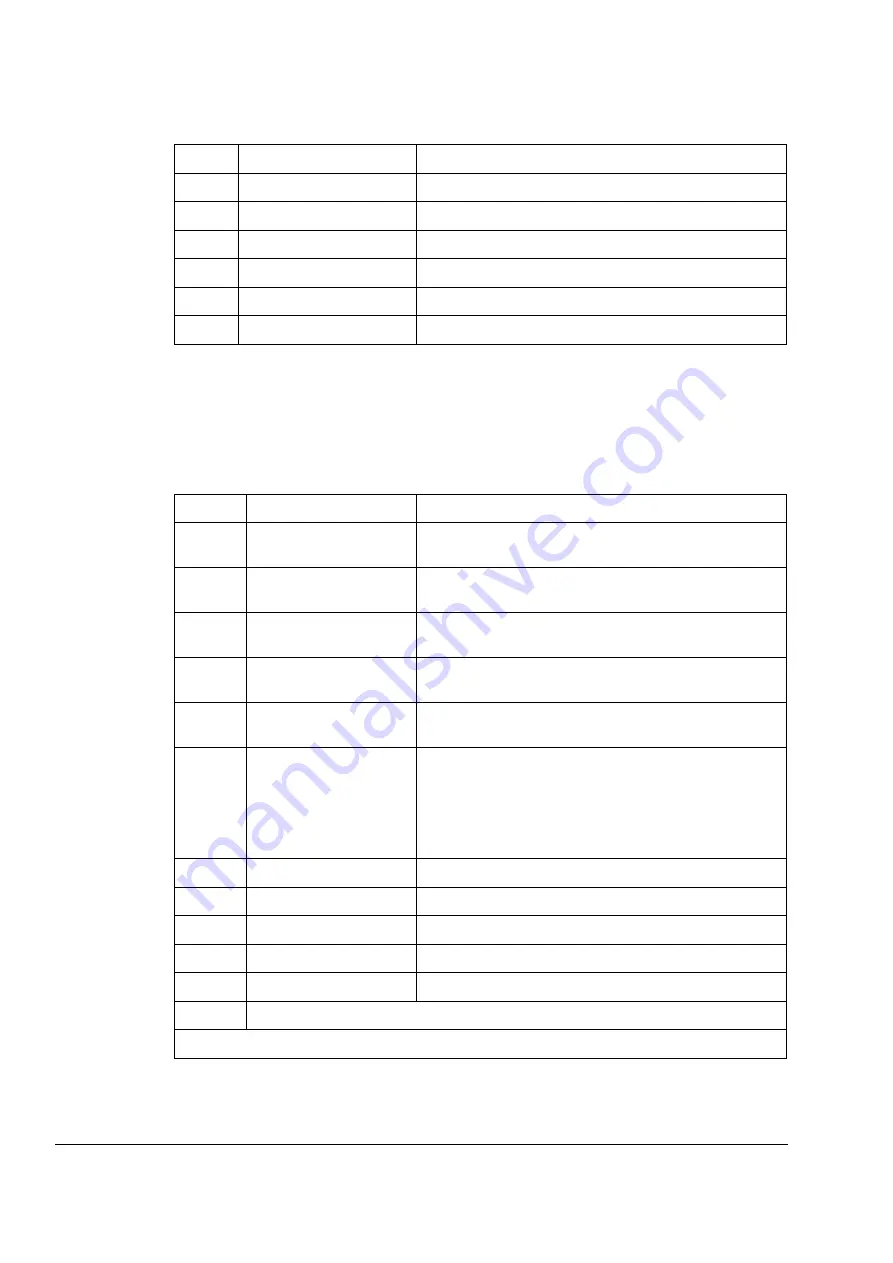

03.30 LIMIT WORD INV

The LIMIT WORD INV Word includes faults and warnings which occur when the

output current limit of the drive is exceeded. The current limit protects the drive in

various cases, for example, in case of integrator overload, high IGBT temperature,

etc.

4380

TEMP DIF xx y

4311

THERMISTOR

bit 2

FF91

T MEAS ALM

bit 6

FF6A

UNDERLOAD

bit 1

FFFB

ZERO POS WARN

FFEF

CTRL LOC DIFF

bit 12

Bit

Name

Description

0

INTEGRAT 200

Current limit at 200% integrator overload. Temperature

model is not active.*

1

INTEGRAT 150

Current limit at 150% integrator overload. Temperature

model is not active.*

2

INT LOW FREQ

Current limit at high IGBT temperature with low output

frequency (<10 Hz). Temperature model is not active.*

3

INTG PP TEMP

Current limit at high IGBT temperature. Temperature model

is not active.*

4

PP OVER TEMP

Current limit at high IGBT temperature. Temperature model

is active.

5

PP OVERLOAD

Current limit at high IGBT junction to case temperature.

Temperature model is active.

If the IGBT junction to case temperature continues to rise in

spite of the current limitation, the PP OVERLOAD alarm or

fault occurs. See chapter

6

INV POW LIM

Current limit at inverter output power limit.

7

INV TRIP CUR

Current limit at inverter overcurrent trip limit.

8

OVERLOAD CUR

Maximum inverter overload current limit. See par.

9

CONT DC CUR

Continuous dc-current limit.

10

CONT OUT CUR

Continuous output current limit (I

cont.max

).

11 … 15

Reserved

*Not active with ACS800 Default settings.

Code

Description

Application/Fault Word Status Bit

Содержание ACS 800 Series

Страница 1: ...ACS800 Firmware Manual Crane Control Program N697 ...

Страница 4: ......

Страница 26: ...Start up and control through the I O interface 26 ...

Страница 36: ...Quick start up guide 36 ...

Страница 52: ...Control panel 52 ...

Страница 105: ...Program features 105 Figure Control diagram for Shaft synchronisation executed in 20 ms ...

Страница 126: ...Program features 126 The figures below show speed limits according to different load conditions ...

Страница 128: ...Program features 128 ...

Страница 150: ...Application macros control location EXT1 EXT2 150 ...

Страница 228: ...Actual signals and parameters 228 ...

Страница 299: ...Adaptive Programming examples for crane control 299 ...

Страница 305: ...Adaptive Programming examples for crane control 305 ...

Страница 312: ...Adaptive Programming examples for crane control 312 The following figures show the previous example enlarged ...

Страница 314: ...Adaptive Programming examples for crane control 314 The following figures show the previous example enlarged ...

Страница 318: ...Analogue Extension Module 318 ...

Страница 332: ...Additional data actual signals and parameters 332 ...

Страница 333: ...DriveWindow 333 DriveWindow DriveWindow connected to the ACS800 RMIO RDCO board and channel CH3 ...

Страница 334: ...DriveWindow 334 ...

Страница 335: ...Control block diagrams 335 Control block diagrams ...

Страница 336: ...Control block diagrams 336 ...

Страница 337: ...Control block diagrams 337 ...

Страница 338: ...Control block diagrams 338 ...

Страница 340: ...www abb com drives www abb com drivespartners Contact us 3AFE68775230 Rev E EN 2012 09 25 ...