Mounting

IM/265D/V-EN-02 265Dx,

265VS

27

Pos: 11.10 /Überschriften/1.1/1-spaltig/D - F/Feuchtigkeit @ 1\mod_1147678490875_3101.doc @ 10923

4.4

Moisture

Pos: 11.11 /Montage/Druck/Druckmessumformer/Druckmessumformer 265Dx, 265Vx/Feuchtigkeit @ 17\mod_1201093272078_3101.doc @ 153793

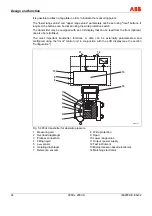

Use suitable cables and tighten cable glands securely. The transmitter can also be protected

against the ingress of moisture by routing the connecting cable downward before securing it.

This allows rain and condensation to drip down. This is especially important for installation in

outdoor areas and rooms that are exposed to moisture (e.g., due to cleaning processes) or on

cooled or heated tanks.

M00387

Fig. 6: Steps for preventing the ingress of moisture

Pos: 11.12 /Überschriften/1.1/1-spaltig/M - O/Messleitungen @ 5\mod_1163153163140_3101.doc @ 48153

4.5

Measuring pipes

Pos: 11.13 /Montage/Druck/Druckmessumformer/Druckmessumformer 265Dx, 265Vx/Messleitungen @ 5\mod_1164011931218_3101.doc @ 48685

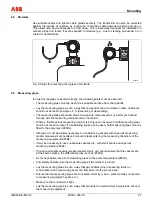

In order for the pipes to be laid correctly, the following points must be observed:

• The measuring pipes must be as short as possible and free from sharp bends.

• Lay the measuring pipes in such a way that no deposits can accumulate in them. Gradients

should not be less than approx. 8 % (ascending or descending).

• The measuring pipes should be blown through with compressed air or, better yet, flushed

through with the measuring medium before connection.

• Where a fluid/vaporous measuring medium is being used, the liquid in both measuring pipes

must be at the same level. If a separating liquid is being used, both measuring pipes must be

filled to the same level (265Dx).

• Although it is not absolutely necessary to use balancing vessels with vaporous measuring

media, measures must be taken to prevent steam entering the measuring chambers of the

measuring equipment (265Dx).

• It may be necessary to use condensate vessels, etc., with small spans and vaporous

measuring media (265Dx).

• If using condensate vessels (steam measurement), you should ensure that the vessels are

at the same height in the differential pressure lines (265Dx).

• As far as possible, keep both measuring pipes at the same temperature (265Dx).

• Completely depressurize the measuring pipes if the medium is a fluid.

• Lay the measuring pipes in such a way that gas bubbles (when measuring fluids) or

condensate (when measuring gases) can flow back into the process line.

• Ensure that the measuring pipes are connected correctly (+ and - pressure sides connected

to measuring equipment, seals, etc.).

• Make sure the connection is tight.

• Lay the measuring pipes in such a way that prevents the medium from being blown out over

the measuring equipment.

Pos: 12 /======= Seitenumbruch ======== @ 0\mod_1126532365768_3101.doc @ 3830

Содержание 265DS

Страница 87: ......