7

STAGES OF CLEAN WATER PRODUCTION IN REVERSE OSMOSIS SYSTEM

Feed water pressure must be minimum 3 bar for reverse osmosis system to work. If the feed water pressure

is not sufficient, the system can be reinforced with a pump.feed water passes through the following filtrations

respectively;

• 1st Stage: 5 micron pp sediment filter. The pre-sediment filter retains suspended materials and particles in

the water and protects successive filtrations, especially the membrane filter. (1 mm=1000 micron).

• 2nd Stage: Activated carbon filter removes pollutants, which are harmful to human health and membrane

filter, by retaining organic substances and high amounts of cancerogenic chlorine and chlorine compounds.

• 3rd stage: Block carbon filter is used for more sensitive particle filtration to retain the suspended materials in

the water.

• 4th stage: Membrane filter. The semi-permeable membrane with 8-12 angstrom pores retains bacteria,

viruses and heavy metals in the water at 95-98% and pollutant runs to the drainage through wastewater part

of membrane.

• 5th stage: Last carbon filter (post carbon). Water runs through the carbon filter at the last stage to provide

clean and extremely safe drinking water.

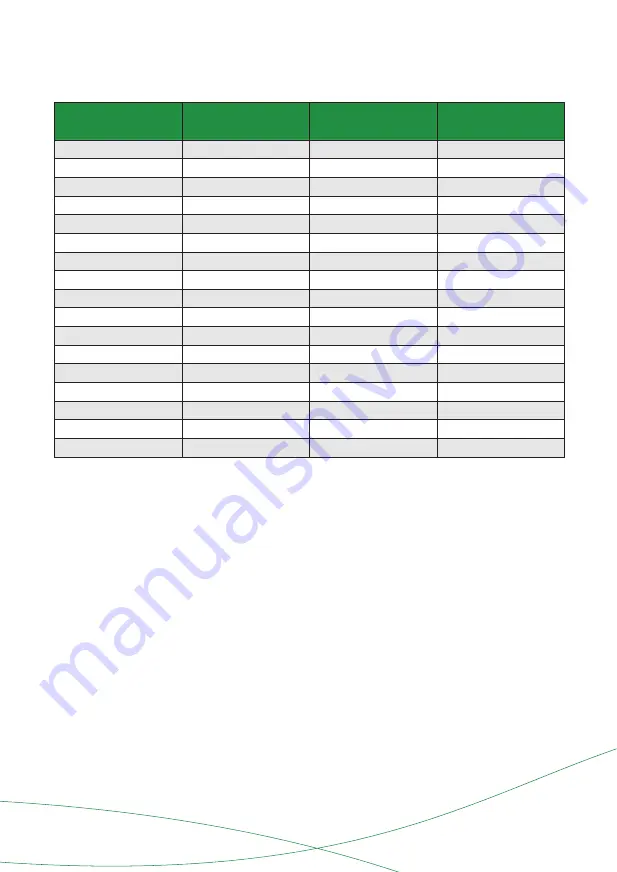

ION REMOVAL IN REVERSE OSMOSIS

WORKING PRINCIPLE

ION AND ORG.

PESTICIDE

REMOVAL ( % )

ION AND ORG. PES-

TICIDE

REMOVAL ( % )

Aluminum

97-98

Nickel

97-99

Ammonium

85-95

Nitrate

93-96

Arsenic

94-96

Phosphate

99+

Magnesium

96-98

Potassium

92

Bicarbonate

95-96

Radioactivity

95-98

Bromide

93-96

Radium

97

Cadmium

96-98

Selenium

97

Calcium

96-98

Silica

85-90

Chloride

94-95

Silver

95-97

Chromate

90-98

Sodium

92-98

Chromium

96-98

Sulfate

99+

Copper

97-99

Zinc

98-99

Cyanide

90-95

Boron

50-70

Fluoride

94-96

Borate

30-50

Iron

98-99

Mercury

96-98

Lead

96-98

Bacteria

99+

Mangan

96-98

Virus

99+