REPLENISHMENT OF SALT SUPPLY:

The salt storage capacity of the brine tank is approximately

180 lbs (82 kg). During each regeneration a specific amount

of salt is consumed, thus requiring its periodic replenish-

ment (the frequency and salt dosage level is dependent

on the regeneration schedule). Always replenish salt

before the supply is exhausted for a continuous supply

of softened water.

TYPE OF SALT TO USE:

Any type of water softener salt may be used. There are

advantages and disadvantages to every type of salt.

Please ask your local dealer for his advice. Your unit is

designed to compensate for the disadvantages. However

the use of block salt is not encouraged due to its poss-

ible problems in making enough brine for regeneration

purposes.

BRINE TANK CLEAN-OUT:

To prevent service problems the brine tank should be

emptied and flushed out with a garden hose when dirt and

other insolubles accumulate.

Steps to follow:

(1) Disconnect brine line at either end.

(2) Turn brine tank upside down and discard old salt.

(3) Rinse out with a garden hose.

(4) Reconnect brine line.

(5) Before loading salt, using a pail or garden hose add

enough water to the brine tank to cover the salt grid lower

shelf on 15” x 15” x 34” brine tank at least one (1) inch in

depth. Then add initial salt to brine tank and add one (1)

cup of unscented laundry bleach to the brine well.

(6) Perform approximately once a year if rock salt is

used; with other types of salt, approximately once every

other year.

PREVENTING IRON-FOULING OF MINERAL BED:

If iron is present in the water supply, the softener mineral

bed will eventually become iron-fouled, resulting in reduced

softening capacity and rust-stained fixtures. Mixing one to

two ounces of IRON-X Mineral Cleaner with every 80 lbs.

of salt added to brine tank will help minimize these prob-

lems from occurring. IRON-X is available from your dealer.

PERIODICALLY CHECK TIME OF DAY SETTING:

Power outages will cause “TIME OF DAY” setting to

become incorrect. To correct,

refer to Section 4 on how

to correct.

MALFUNCTION OF UNIT:

Your water softener, under normal conditions, should pro-

vide years of virtually trouble-free service; however, since

it is a mechanical device, it can malfunction.

(Refer to

Section 5, SERVICE INSTRUCTIONS, if necessary).

CHANGE OF OPERATING CONDITIONS:

Should your family size, your water usage habits, or your

water quality change, the regeneration program settings

may have to be adjusted. Consult your dealer if any of the

above occur.

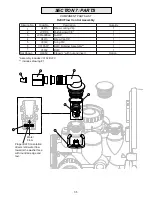

SPECIAL SERVICE INSTRUCTIONS:

Under normal circumstances, removal of valve should

never be required. However, if it must be removed, it can

be done by disassembling the quick release clamp, by

removing latch. Pressure should be relieved before at-

tempting any disassembly. Upon reassembly, all o-rings

should be lubricated with silicone grease. Reassemble

clamp as shown in Figure 6. MAKE SURE ARROWS ON

LATCH SIDE OF CLAMP ARE ALIGNED.

Figure 6. CLAMP ASSEMBLY

4-1

SECTION 4: MAINTENANCE