SECTION 3: REGENERATION INSTRUCTIONS

INSTRUCTIONS FOR USING REGENERATION FREQUENCY SCHEDULES:

1) Determine ADJUSTED HARDNESS by adding three (3) times the iron content in parts per million (ppm) to the hardness in grains

per gallon (gpg). The resulting number is ADJUSTED HARDNESS.

EXAMPLE: Hardness is 14 gpg and iron is 2 ppm. ADJUSTED HARDNESS is 20 gpg (14 plus 3 times 2).

2) Select REGENERATION FREQUENCY SCHEDULE corresponding to the model. Locate box intersected by DAILY WATER USE

and ADJUSTED HARDNESS (if ADJUSTED HARDNESS is between two numbers in schedule, use higher number). Number in

box represents FREQUENCY or NUMBER OF times per 12 DAYS timer should be set to regenerate. Refer to HOW TO SET TIME

CLOCK REGENERATION CONTROL to set correct frequency.

EXAMPLE:

Rounding is always down. You have Model HWS050 (13,000 grain capacity at factory salt setting), 450 gpd usage and 5

gpg adjusted hardness. Refer to appropriate REGENERATION FREQUENCY SCHEDULE and locate box intersected by 450 gpd and

5 gpg adjusted hardness. The fi gure "3" in box indicates a REGENERATION frequency of THREE TIMES PER 12 DAYS (if a "1", "2",

"4", etc. were in box, frequencies of once, twice and four times per twelve days, respectively, would be indicated.) This can be calculated

as 13,000/(5 x 450) = 5.8 days between regeneration, rounding down to every 4 days or 3 times in a 12 day cycle, as indicated.

3-1

REGENERATION FREQUENCY SCHEDULES

(TIMES PER 12 DAYS)

0

0

1

S

W

H

:

L

E

D

O

M

0

5

0

S

W

H

:

L

E

D

O

M

Gallons

Per

Day

50

100

150

200

250

300

350

400

450

500

HARDNESS - GPG

5

1

1

1

1

2

2

2

2

2

3

10

1

1

2

2

3

3

3

4

4

4

15

1

2

2

3

4

4

6

6

6

6

20

1

2

3

4

4

6

6

6

12

12

25

2

3

4

4

6

6

12

12

12

12

30

2

3

4

6

6

12

12

12

NR

NR

35

2

3

6

6

12

12

12

NR

NR

NR

40

2

4

6

6

12

12

NR

NR

NR

NR

NR - Not Recommended

Gallons

Per

Day

50

100

150

200

250

300

350

400

450

500

HARDNESS - GPG

5

1

1

1

1

1

1

2

2

2

2

10

1

1

1

2

2

2

2

3

3

3

15

1

1

2

2

3

3

3

4

4

4

20

1

2

2

3

3

4

4

4

6

6

25

1

2

3

3

4

4

6

6

6

6

30

1

2

3

4

4

6

6

6

12

12

35

2

2

3

4

6

6

6

12

12

12

40

2

3

4

4

6

6

12

12

12

NR

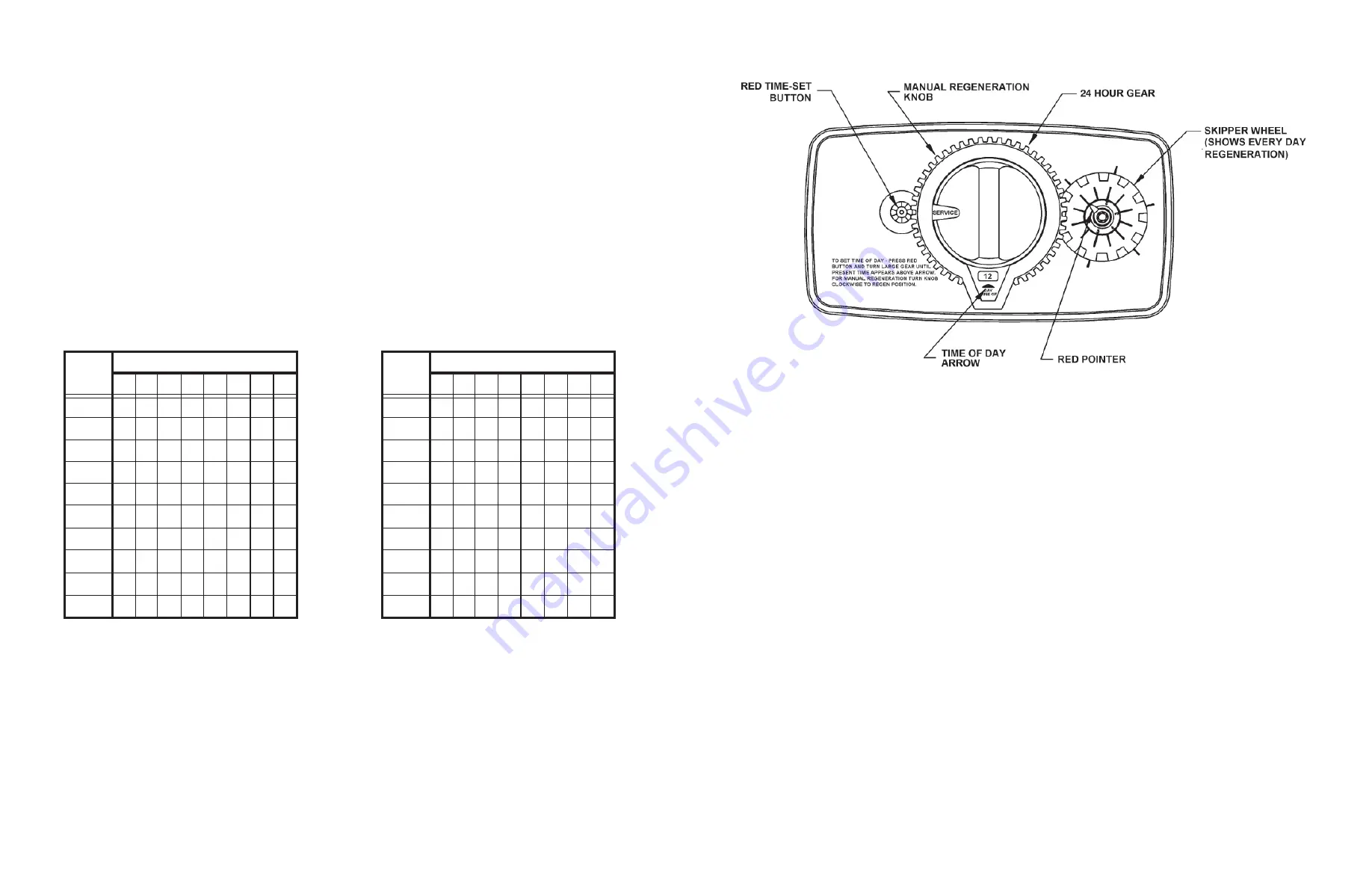

HOW TO SET TIME CLOCK REGENERATION CONTROL

HOW TO SET DAYS ON WHICH WATER SOFTENER IS TO REGENERATE:

Rotate the skipper wheel until the number "1" is at the red pointer. Set the days that regeneration is to occur by sliding tabs on the skip-

per wheel outward to expose trip fi ngers. Each tab is one day. Finger at red pointer is tonight. Moving clockwise from the red pointer,

extend or retract fi ngers to obtain the desired regeneration schedule.

HOW TO SET THE TIME OF DAY:

1) Press and hold the red button in to disengage the drive gear.

2) Turn the large gear until the actual time of day is opposite the time of day pointer.

3) Release the red button to again engage the drive gear.

4) Time of regeneration is preset for 2:00 a.m.

HOW TO MANUALLY REGENERATE THE WATER SOFTENER AT ANY TIME.

Turn the manual regeneration knob clockwise.

A slight, clockwise movement of the manual regeneration knob engages the program wheel and starts the regeneration program.

The black center knob will make one revolution in the following approximately three hours and stop in the position shown in the drawing

(SERVICE POSITION).

Even though it takes three hours for this center knob to complete one revolution, the regeneration cycle of the unit might be set only

one-third of this time.

In any event, conditioned water may be drawn after rinse water stops fl owing from the water softener drain line.

3-2