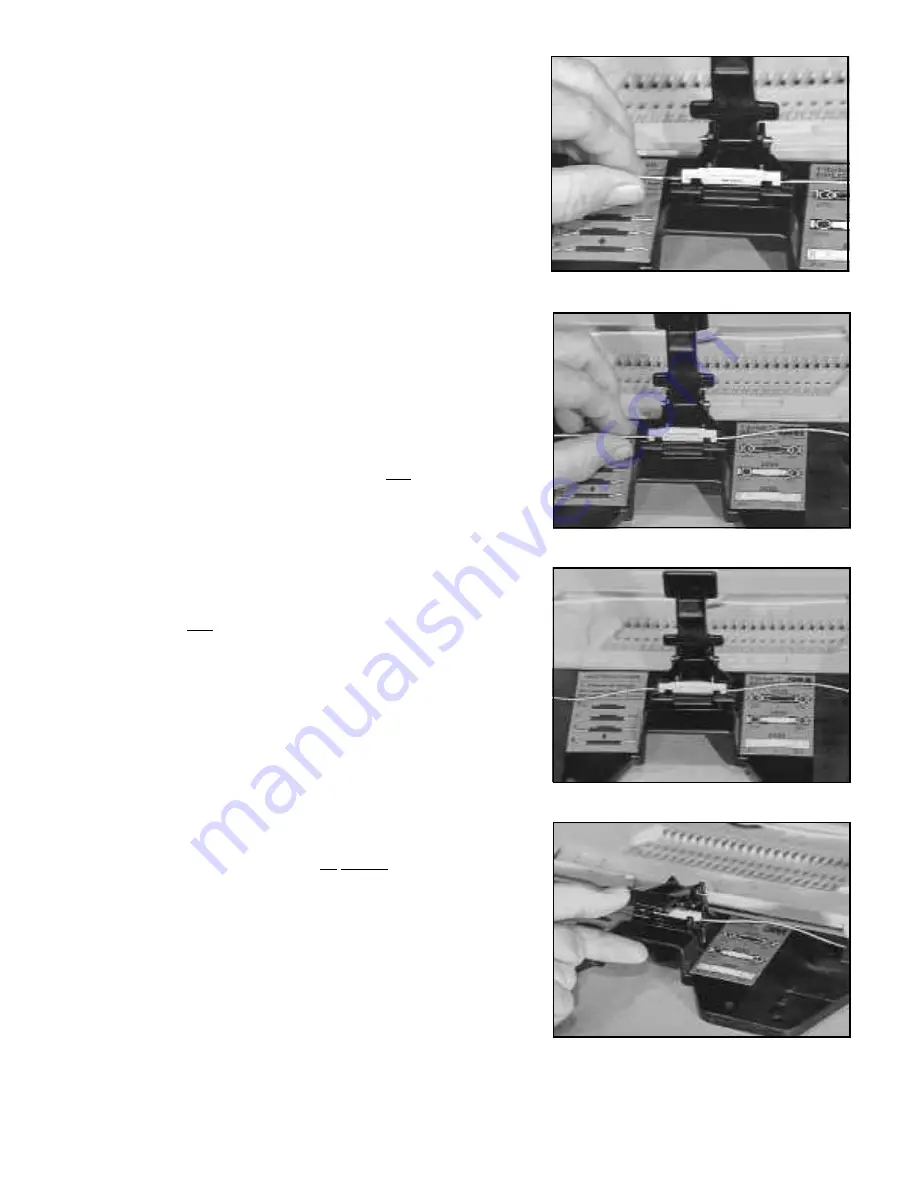

4.06 Gently push the second fiber in small increments straight

through the alignment guide into the fiber entry port. As

the coating of the second fiber enters the fiber entry port,

watch for the bow in the first fiber to increase. This occurs

when the end face of the second fiber contacts the first

fiber and pushes the first fiber slightly back out of the

splice. Continue gently pushing the second fiber until it

meets resistance. Following proper insertion, the second

fiber will be approximately straight but may have up to a .1

inch (3 mm) maximum bow. At this point, the first fiber will

have a larger bow than the second fiber and larger than it

had initially.

4.07 Push the first fiber back against the second fiber until there

are equal bows in both fibers.

Note:

Do not pull on either of the fibers following

establishment of the bows in the first and second

fibers. The fiber ends must be held together by the

compressive forces induced by the bows to produce

a low loss splice.

4.08 Pivot the handle of the Fibrlok Assembly Tool down until it

contacts the cap of the Fibrlok Splice. Squeeze the

handle of the assembly tool as shown in order to close

cap and actuate the splice. When possible, secure the

tool to a work surface for added support. A snap sound

will be heard when the splice is actuated.

4.04 Prepare second fiber (strip, clean and cleave) as described

in Section 3.

4.05 Lay fiber into foam retention pad and begin to insert the

fiber end into the splice, as in 4.01 and 4.02.