9

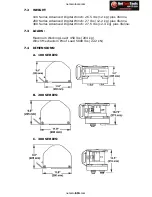

provided by DBI-SALA must meet the geometric requirements

shown in Figure 4. Position the support structure so the load and

the lifeline of the winch can be directed over the work area when

installed. For personnel use, do not position the support structure

where the worker will have to swing under the support structure

to reach the work area. Avoid positioning the support structure

where the working line may abrade against sharp edges.

IMPORTANT:

Position the winch and support structure in a location

which allows the operator to safely use the winch.

C. MOUNTING PLATE:

The Digital Winch is equipped with

a universal mounting plate. The universal mounting plate

is designed to attach to the quick mount bracket and the

advanced series winch mount bracket (see Figure 5) and will

accommodate most other support structures which meet the

requirements specified in section 3.3. See the support system

user manual for mounting information or contact DBI-SALA

for optional mounting kits. When attaching the winch to the

support, one of the attachment features (i.e., bolt or stud)

must capture the structural carrying handle.

D. WELDED INSTALLATIONS:

If welding the mounting bracket

to a support structure it is recommended that the welding be

done by a certified welder. Portions of the mounting bracket

that have been exposed due to welding should be painted or

otherwise protected from corrosion.

Figure 4 - Required Load Strength

1,900 ft-lbs

moment load

36 in. Min

Recommended

Directional

Sheave

2,500 lbs.

in direction of pull

Left Hand Retrieve

(cable feeds off top)

Right Hand Retrieve

(cable feeds off bottom)

Wire rope

directional sheaves

must have a

minimum tread

diameter of 2.5 in.

625 ft-lbs

moment load

2,500 lbs.

in direction of pull

netzerotools.com

netzerotools.com