®

3Doodler 2.0

WARNINGS & NOTICES

ENGLISH

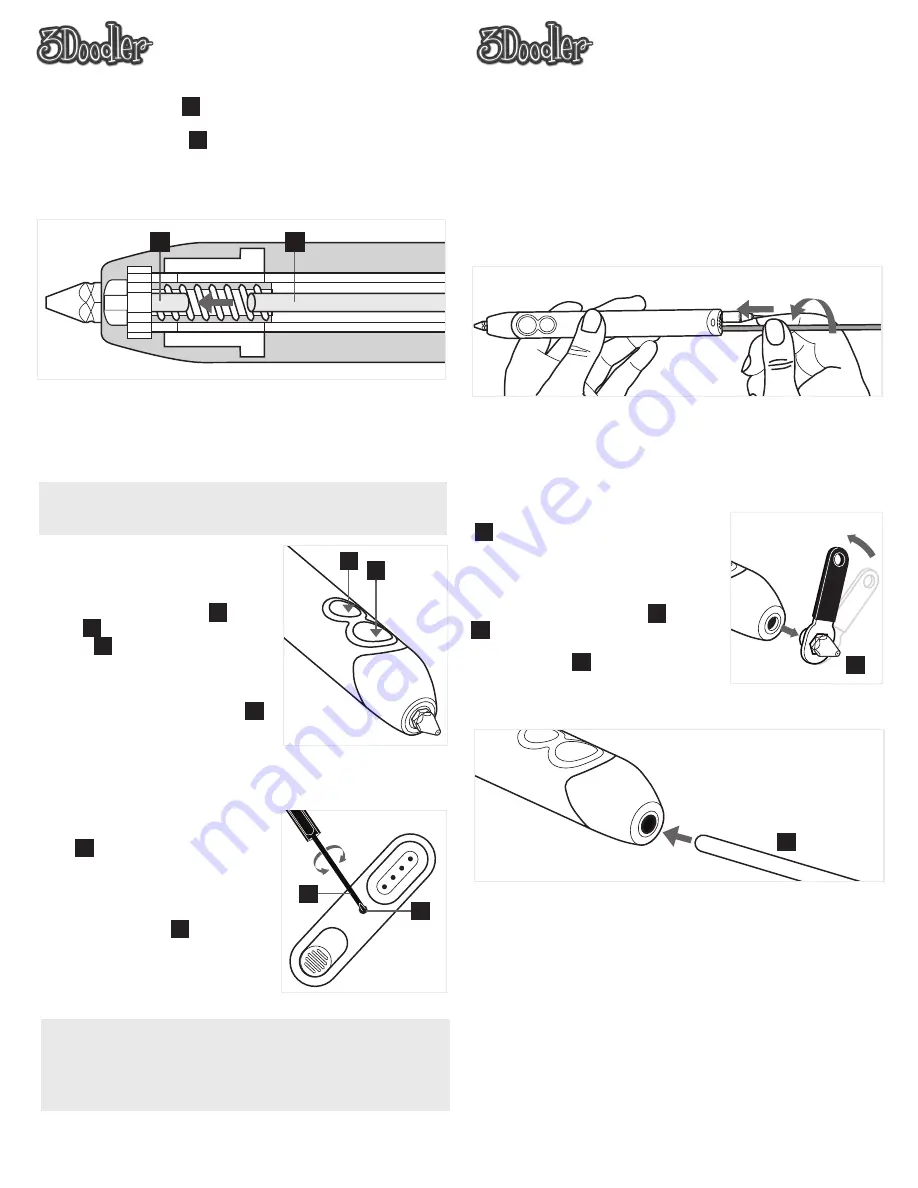

If the plastic/filament is not extruding, it may be because the

existing plastic/filament (A) is too short or has fed beyond the

gearbox, and you will not be able to reverse it. Please use a new

strand of plastic/filament (B) or the Cleaning Tool to feed the

remaining plastic/filament through the pen.

A

B

Step 7:

Power down

To safely turn the pen off, move the slide switch to the OFF

position. Allow the pen to cool completely before storing.

Note: For those of you who are curious, the distance between

the gearbox and the nozzle is less than one inch.

B

A

Otherwise, please press one of the

extrusion buttons and wait for the

3Doodler to heat up again.

2.

Double click either

FAST

(2) or

SLOW

(3) extrusion buttons. The LED

indicator (5) will flash while reversing.

3.

When the plastic/filament stops

moving in reverse you may gently

take it out from the back of the pen .

5

2

3

HI (“High”) = BLUE LED

indicator

LO (“Low”) = GREEN LED

indicator

Step 6:

Unloading/reversing your plastic/filament

To unload the plastic:

1.

Ensure that the device is still at the correct temperature required

for the type of plastic/filament being used:

12

3

2

PRO TIP:

Optimize your melt

temperature; using the mini-screw

driver , tweak your 3Doodler’s melt

tempe/- 5°C, for minor flow

adjustments and expertly consistent

Doodles. To do this, insert the mini

screw driver into the potted

Temperature Adjuster on the control

panel.

Turn the mini screw driver

clockwise to increase the melt

temperature, or anti-clockwise to

decrease the melt temperature.

10

10

13

13

NOTE:

Our 3Doodler is a sturdy and awesome tool, but

like any mechanical device it needs a break now and then.

We suggest giving it (and yourself) some downtime after 2

hours of continuous use (just a 30 minute break or so).

®

3Doodler 2.0

WARNINGS & NOTICES

ENGLISH

TROUBLESHOOTING AND CLEANING THE PEN

If the extrusion of plastic/filament has slowed down, stopped, or if

you are having trouble inserting plastic into the pen, please give the

plastic/filament a gentle clockwise twist while pushing it down the

shaft of the 3Doodler.

If the nozzle is loose, please gently tighten it, stopping when you

first feel resistance, and being sure to do so while the pen is hot.

Try to extrude again.

WARNING: DO NOT force the nozzle or

overtighten it, as you could permanently damage your

3Doodler.

(4) speed buttons to set the pen in

reverse. While reversing insert the

Unblocking Tool through the front end

of the pen and gently push out any

If this does not work, we suggest cleaning the 3Doodler. Please

follow the steps below:

2.

Start by using the nozzle removal tool

and unscrew the nozzle anti-clockwise

while the pen is hot. Please be careful not

to touch the nozzle!

3.

Once you have removed the nozzle,

double click either the

FAST

(3) or

SLOW

2

3

14

excess plastic, removing it from the back of the pen.

1.

Ensure the LED light is

BLUE

or

GREEN

before starting this

process (indicating that the pen is hot).

8

Turn nozzle

removal tool

anti-clockwise

14

4.

Turn the pen off and allow it to cool down a little, but not fully.

Screw the nozzle on clockwise a few turns, but don’t tighten it yet.

Turn the pen back on; once it’s hot and the LED is either blue or

green, tighten the nozzle with the nozzle removal tool, stopping

when you first feel resistance.

WARNING: DO NOT force the

nozzle or overtighten it, as you could permanently damage

your 3Doodler.

8