Step

1

Model Identification and

Mounting

Connect Motor and

Line Power

Step

2

Step

3

Page 1 of 4

WARNING! Fire Hazard. Only connect ground wiring to

designated ground terminals. Do not connect the following

terminals to earth ground.

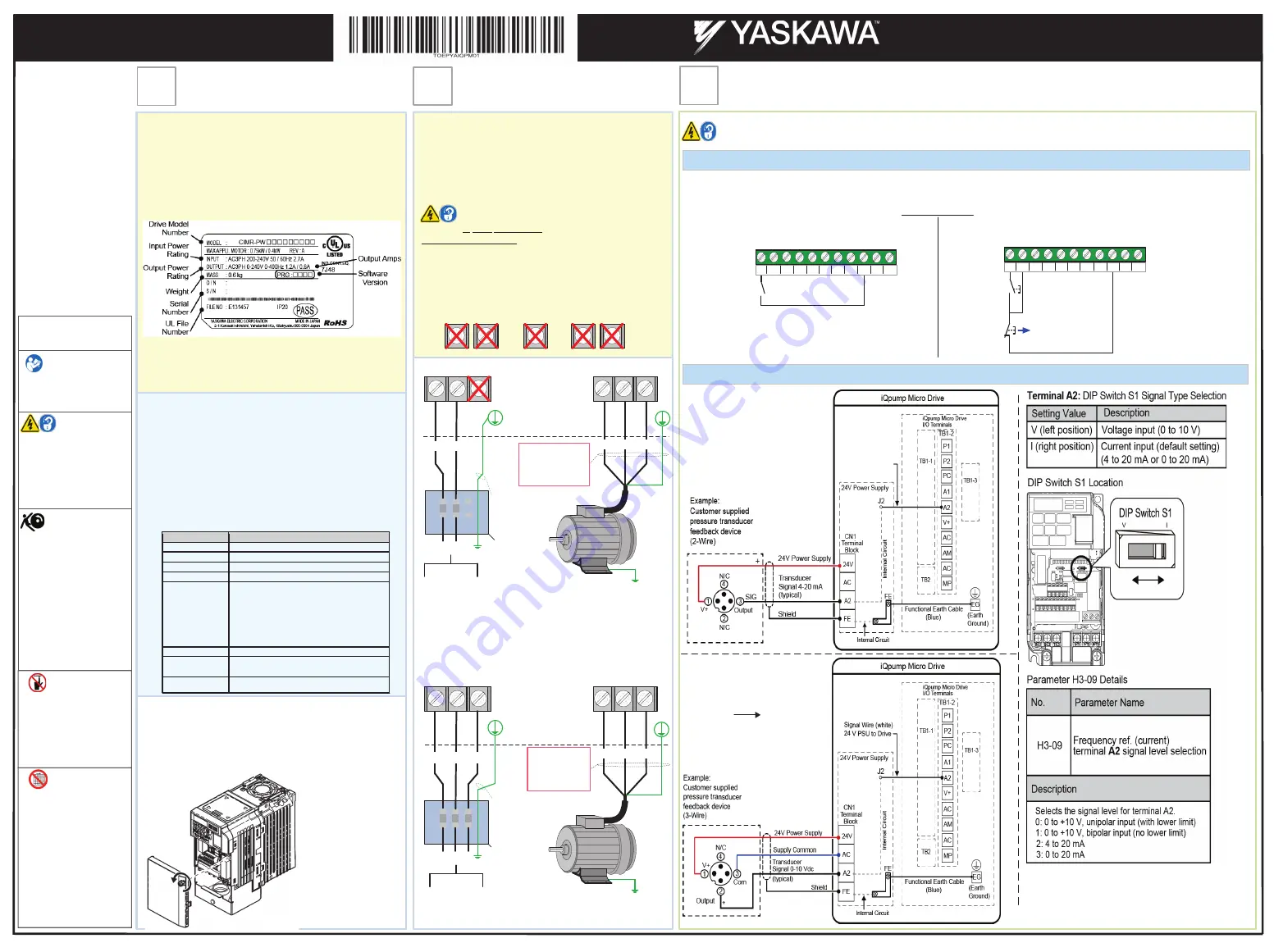

9. Figures 1 and 2

show the electrical connections for input

power and motor terminals.

Select the proper figure for the

model being installed

(Refer to Step 1).

WITH POWER OFF make the appropriate connections.

Follow good wiring practices and all applicable electric codes.

Ensure the equipment is grounded properly

as shown in Figure 1.

W

WARNING! Hazardous Voltage. After the power is

OFF, wait at least five minutes until the charge indicator

extinguishes completely before touching any wiring, circuit

boards or components.

Verify the drive is properly sized for single phase input power. The drive

input supply voltage must be equal to or greater than motor rated voltage

for best performance.

*

U/T1 V/T2 W/T3

3Ø Induction

motor

1Ø Input Power

Connect

frame to

ground

Input

Protection

(Fuse or C.B.)

To change direction

of motor rotation,

swap any

two of the

three motor leads

(Refer to Step 2)

L1 L2

Figure 1:

Input Power and Output Motor Electrical

Connections for Single Phase Input iQpumpMicro

SINGLE PHASE

INPUT

iQpump Micro

Connect to chassis

ground

R/L1 S/L2

U/T1 V/T2 W/T3

3Ø Induction

motor

3Ø Input Power

L1 L2 L3

Figure 2:

Input Power and Output Motor Electrical

Connections for Three Phase Input iQpump Micro

R/L1 S/L2 T/L3

THREE PHASE

INPUT

iQpump Micro

-

+1

+2

(S/L2)

(R/L1)

(U/T1) (V/T2) (W/T3)

(U/T1) (V/T2) (W/T3)

To change direction

of motor rotation,

swap any

two of the

three motor leads

(Refer to Step 2)

Connect

frame to

ground

Input

Protection

(Fuse or C.B.)

Connect to chassis

ground

(R/L1) (S/L2) (T/L3)

B1

B2

1. Verify the correct drive model and ratings.

2. Locate the drive nameplate and your order information.

3. Verify the drive MODEL No. matches the line item(s) on

your order, to confirm receipt of the correct model.

4. Locate the nameplate of motor that will be connected to the

drive.

5. Confirm the motor nameplate Amperage, Voltage, and

Frequency (Hz) are within the O

Output specifications shown on

the drive nameplate.

·

Verify main input power source is adequate by reviewing

the Input specifications drive nameplate.

Mechanical Installation

·

Follow the above procedure for each iQpumpMicro and

motor combination.

7. Adhere to environmental specifications to avoid damage to

the equipment and to maintain safety. For NEMA 4 model

environmental conditions, refer to instructions supplied with

the product.

Removing and Attaching the Terminal Cover

6. Mechanical installation and mounting footprint vary by

drive model. Refer to the iQpump Micro User Manual

No.TOEPYAIQPM03

Section 2 Mechanical Installation,

for

mechanical installation details. Refer to the proper

clearances required for adequate ventilation in systems

containing multiple drives.

8.

Improper removal of the the drive’s protective covers and

conduit bracket (NEMA 1) can cause damage to the drive.

Adhere to iQpump User Manual, Section 3,

Protective

Covers

to avoid drive damage.

NEMA 1

Installation Environment (IP20/NEMA TYPE 1)

Environment

Conditions

Installation Area

Indoors

Ambient Temperature + 14 to 104 °F (-10 to + 40 °C) NEMA Type 1 Enclosure

Humidity

95% RH or less and free of condensation

Storage Temperature -20 to + 60 °C

Surrounding Area

Install the drive in an area free from:

•

oil mist and dust

•

metal shavings, oil, water, or other foreign materials

•

radioactive materials

•

combustible materials (e.g., wood)

•

harmful gases and liquids

•

excessive vibration

•

chlorides

•

direct sunlight.

Altitude

1000 meters or lower

Vibration

10 to 20 Hz at 9.8 m/s2

20 to 55 Hz at 5.9 m/s2

Orientation

Install the drive vertically to maintain maximum cooling

effects.

iQpump Micro control and transducer feedback signal wiring connections.

WARNING! Hazardous Voltage. Contact may cause electric shock or burn. Turn-off and lock-out system and facility power before servicing

Remove the terminal cover to gain access to the control terminals. (Step 1.)

10. SELECT START / STOP CONTROL METHOD

b1-02

NOTE: Refer to the iQpump Micro User Manual,

(Document No. TOEPYAIQPM03) to program the iQpump Micro drive

for network communication control.

11. TRANSDUCER FEEDBACK SIGNAL WIRING [REFER TO PAGE 7 OF 12 FOR 24 V POWER SUPPLY INSTALLATION]

Initialize the iQpump Micro

Set parameter A1-03 = 3330

to use 3-Wire Control

Refer to:

Quick Start Guide

TOEPYAIQPM02

The iQpump Micro is D

DEFAULT SETUP TO START/STOP FROM THE KEYPAD (digital operator). If this is the preferred start/stop method then

continue to the feedback signal connection section. Please refer to the wiring diagram below to start/stop the iQpump Micro using an external switch

or contact.

S3

S5 S6 S7 HC SC H1 RP

S2

S4

S1

Forward

Run

S3

S5 S6 S7 HC SC H1 RP

S2

S4

S1

Start

Switch

Stop

Switch

Normally

Open

Normally

Closed

Use for maintained contacts

iQpump Micro Terminals TB1-1

iQpump Micro Terminals TB1-1

3-Wire Control

2-Wire Control

Wiring Diagrams

3-Wire, 0-10V Transducer

2-Wire, 4-20mA Transducer

Set DIP switch S1 to V position

for use with 0

–

10V Transducer

See far right

NOTE: Transducer wire colors and

numbering may vary depending on

feedback device used,

consult feedback device manual.

NOTE: Transducer wire colors and

numbering may vary depending on

feedback device used,

consult feedback device manual.

Selecting Start/Stop and Speed Method

WARNING!

Read and understand

users manual before

using this equipment

.

This Quick Start

Procedure will help

you configure the

iQpump Micro (drive)

for test run operation

and basic set-up for

simplex pump

application.

Refer to the User

Manual No.

TOEPYAIQPM03,

for detailed

instructions and to

configure the drive

for each specific

installation site.

Safety Symbols in

this Document

W

WARNING!

Hazardous Voltage.

Contact may cause

electric shock or burn.

Turn-off and lock-out

system and facility

power before servicing.

WARNING!

Stay Clear- Equipment

starts automatically.

Clear all personnel

from equipment, install

shields or guards,

locate and verify

emergency SHUT-OFF

is functional. Failure to

comply may result in

serious injury to

personnel.

WARNING!

Improper Operation

Sequence. DO NOT

RUN THE MOTOR.

Failure to comply may

result in serious injury

to personnel.

WARNING!

Do not operate

equipment with covers

or guards removed.

Install or replace cover

and/or guards before

operation. Failure to

comply may result in

serious injury to

personnel.

R

R

R d

d

St

Yaskawa America, Inc., 2121 Norman Drive South, Waukegan, IL 60085, (800) YASKAWA (927-5292) Fax (847) 887-7310, [email protected], www.yaskawa.com, Document Number: TOEPYAIQPM01

11/2014 © Yaskawa America, Inc.

Page 1 of 12

iQpump Micro AC Drive

Simplex Quick Start Procedure