Reviews:

No comments

Related manuals for BV410D-GS02-QM-S

T12

Brand: Gallagher Pages: 13

TC1200

Brand: Datalogic Pages: 160

Charge Analyzer 711

Brand: 3M Pages: 26

BC2604

Brand: Baracoda Pages: 23

appLS07DESK

Brand: aqprox! Pages: 39

Magellan 2200VS omega

Brand: PSC Pages: 382

ALH-900h

Brand: Alien Pages: 41

DynaPAD

Brand: Magtek Pages: 2

E01FL

Brand: Billow Pages: 90

BluScan

Brand: IDTECH Pages: 137

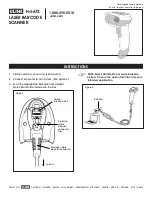

H-6672

Brand: U-Line Pages: 3

20789

Brand: Lindy Pages: 60

XT5-40 Series

Brand: BIXOLON Pages: 2

04-0106-EN

Brand: Intratone Pages: 2

04-0108

Brand: Intratone Pages: 4

PRX-2

Brand: Viking Pages: 4

OPR 3101

Brand: Opticon Pages: 2

SCANTEAM 3470 CCD

Brand: Welch Allyn Pages: 11