SSU

UN

NSSTTAARR M

MAAC

CH

HIIN

NEERRYY C

CO

O..,, LLTTD

D..

M

ME

EE

E--0

06

61

11

11

17

7

R

User’s

Manual

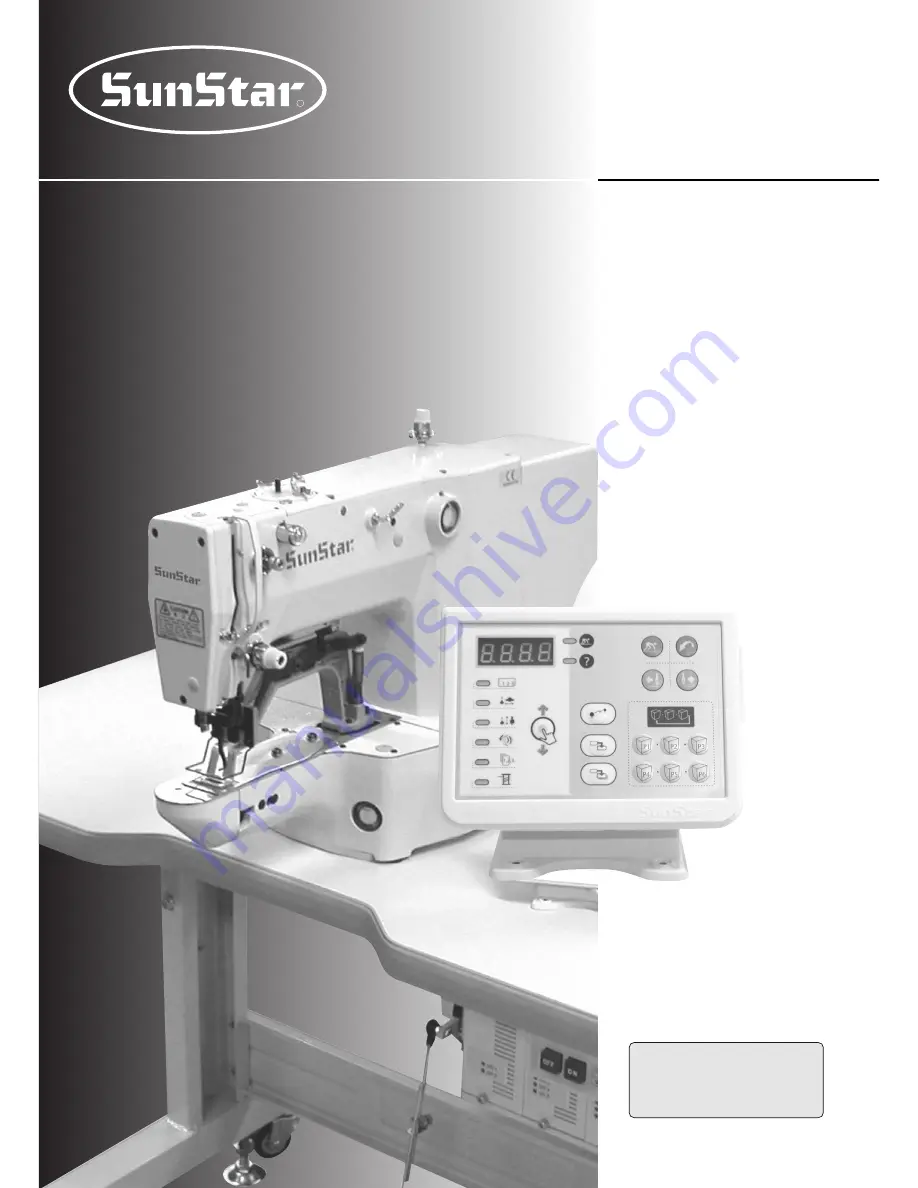

SPS/E-Bartacking Series

SPS/E-Button Sewing Series

Electronically Controlled

Bartacking Machine

(Electronic Control Part)

Electronically Controlled

Button Sewing Machine

(Electronic Control Part)

1) For proper use of the machine,

thoroughly read this manual before use.

2) Keep this manual in a safe place for

future reference in case the machine

breaks down.