Installation Sheet

November, 2016

Supersedes January 2016

s

E87010-A0105-T003-A6-CLM0

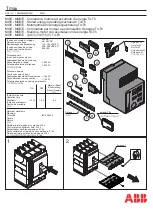

Lighting and Heating Contactor

60, 100, 200 Amp

2, 3, 4, 5 Pole

Magnetically Latched

A5E31166448A-006

Siemens Industry, Inc. 5300 Triangle Parkway, Norcross, GA 30092

Contactor Rating

Catalog Number

CLM0D... CLM0E... CLM0F...

Cont. Current Rating, Amp.

200

100

60

Tungsten

Max. Volts, line-line

480

480

480

Max. Volts, line-Neutral

277

480

277

480

480

277

Ballast

Max. Volts, line-line

Max. Volts, line-Neutral

346

600

600

600

346

600

600

Heating

Max. Volts, line-line

600

600

600

Max. Volts, line-Neutral

346

30

480

277

600

346

600

346

30

480

277

600

346

600

30

480

277

600

346

600

346

600

600

600

600

346

Table 1

Theory of Operation

Each contactor contains a permanent magnet built into its struc-

ture that will maintain the contactor in its energized state indefi

-

nitely without using control power. When energized, DC voltage

is applied to produce a magnetic field that reinforces the polarity

of the permanent magnet and the contactor closes. Immediately,

the current to the coil is disconnected by the coil clearing aux-

iliary contact. In order to open the contactor, it is necessary to

create a field through the OFF coil in the reverse direction to the

permanent magnet. This momentarily cancels the magnetic at-

traction and the contactor drops out.

Each CLM contactor has an electronic control module

“CLMKCMR” which is used to energize and close the contactor

and for the release circuit. It is designed for short time actuation

of 1-3 cycles only. All coils are designed with a small wattage

resistor in addition to a diode at coil voltages higher than 120

volts.

Remote solid state switching devices have ‘off state’

leakage currents. They may also pass utility transient voltages

through to the device electronics.

Magnetically latched CLM lighting and heating contactors can

control tungsten, fluorescent and metal vapor lamp or heating

loads. (Table 1 below shows the voltage and current rating for

various loads). Each contactor and its associated load should be

protected against short circuits by a suitable branch circuit pro-

tective device selected in accordance with the National Electric

Code (NEC).

Description

The low level ‘off state’ voltages are insufficient to actuate

the contactor but large enough to burn out the resistors.

Normal actuating voltages are quickly disconnected from

the coils and control module by the latch clearing contacts.

Coil and module failures are possible when used

with solid

state relays and PLC outputs. 24-volt systems are ok to use,

but 120 volts and above should be discouraged. If higher

voltages cannot be avoided, an interposing relay should be

used.

Care should be taken when servicing that leads do not be-

come changed from their factory installed terminals, or im

-

proper operation and possibly permanent damage to the

contactor could result.

Table 1 -

This industrial type contactor is designed to be installed, operated, and

maintained by adequately trained personnel. These instructions do not cover all

the variations of all of the topics covered herein. Contact your local sales office if

you have questions regarding the product.

CAUTION -

Device sensitive to current polarity.

Risk of damage to this device.

Do not apply AC voltage directly to the coil terminals of this device!

The permanent magnet will be demagnetized and the rectifier will be

damaged if alternating current or wrong polarity direct current is applied

directly to the coil.

CAUTION -

High inrush.

Can cause damage to this device.

Avoid attempting to manually latch or delatch the contactor.