Sistemi elettronici

di Aperture Porte e Cancelli

SATURN

MOUNTING AND CONNECTING INSTRUCTIONS

SATURN

is a motor reducer designed for the automation of

sliding gates with grease lubrication of the gear in the

600

version; in

oil bath

in the

1000

and

2000

versions.

The irreversibility of the motor reducer

allows a perfect and safe

gate closing, and makes the installation of an elecric lock

unneccessary. In case of electric power cut, the lock device

placed on the front part of the motor reducer allows the manual

opening and closing. The operator is equipped with an electronic

clutch device in the

600

version and with an

adjustable

mechanical clutch

in the

1000

and

2000

versions, which

guaranties a thrust adjustment on the gate, furthermore the

electronic inversion system

(optional) through

encoder

makes out of the Saturn motor reducer a safe and reliable

operator allowing in a simple way to respect the laws in force in

the country where the product will be installed.

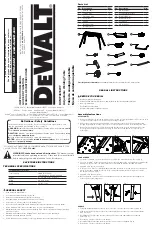

1

Adjustable foundation plate

2

Anchor bolts

3

Pinion protection

4

Adjusting screws cover

5

Pinion

6

Reducer release lever

TECHNICAL DATA

Power supply

Power

Absorbed current

Motor capacitor

Working frequency

Working Temperature

Thermoprotection

Weight

Anticrushing clutch

Protection degree

Pinion Z16 (Z20) speed

Maximum torque

Gate maximum weight

Mechanical clutch

I

nductive or mechanical limit switch

230 V (±5%) 50/60 Hz

330W 550W 750W

1,6 A 2,6 A 3,0 A

16 uf 12,5 uf 25 uf

35% 35% 30%

-20°C +55°C

150°C

12 Kg 13 Kg 14,5 Kg

Electronic Electronic/Mechanical

IP55

9,5 (11) m/min

30 Nm 55 Nm 70 Nm

600 Kg 1000 Kg 2000 Kg

no

with or without

yes

600

1000

2000

8

8

9

9

1

1

3

3

6

6

2000 Kg

1800 Kg

1000 Kg

600 Kg

S

A

T

U

R

N

2

0

0

0

S

A

T

U

R

N

1

0

0

0

25%

40%

50%

30%

35%

U

s

e

f

re

q

u

e

n

c

y

G

a

te

m

a

x

im

u

m

w

e

ig

h

t

Motor reducers

7

Screw for mechanical clutch adjustment

(only in 1000 and 2000 models)

8

Electronic unit

9

Oil filling up cap

10

Magnetic encoder

MAIN PARTS DENOMINATION

ENGLISH

SATURN MOTOR REDUCER USING GRAPHIC

1. GATE ARRANGEMENT

Before starting with the installation check if all the gate parts

(fixed and mobile) have a strong and as less as possible

deformable structure, also make sure that :

a) The leaf is rigid and compact;

b) The inferior slideway is perfectly straight, horizontal and

without any obstacles which could obstruct the gate sliding;

c) The inferior sliding wheels are equipped with greasable or

water tightened bearings;

d) The superior slideway has been produced and placed so that

the gate is in a perfect vertical position;

e) Mechanical stops of the leaf are always installed in order to

avoid possible derailment of it.

DIMENSIONS (mm)

1/30

S

A

T

U

R

N

6

0

0

2

2

4

4

5

5

7

7

10

10

S

A

T

U

R

N

6

0

0

S

A

T

U

R

N

1

0

0

0

S

A

T

U

R

N

2

0

0

0

320

345

1

2

5

600 - 1000 - 2000

REV 00 - 04/2007

cod. 67410326