Reviews:

No comments

Related manuals for SAFE-O-TRONIC access LS101

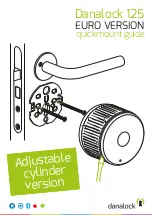

125

Brand: danalock Pages: 32

125

Brand: danalock Pages: 4

Smart Mortise

Brand: Igloohome Pages: 26

MagicLock ML22FOX

Brand: Waeco Pages: 64

MG 1300

Brand: Chamberlain Pages: 2

175 Biometric

Brand: MARKS USA Pages: 4

DT 600

Brand: Hafele Pages: 72

48517

Brand: Safety 1st Pages: 2

HS129

Brand: Safety 1st Pages: 3

86516

Brand: Hama Pages: 4

OneKEY

Brand: inVue Pages: 9

Securitron UnLatch

Brand: Assa Abloy Pages: 8

Union CodeGUARD 5

Brand: Assa Abloy Pages: 16

Weiser 62884 / 01

Brand: Spectrum Pages: 2

6730

Brand: S&G Pages: 6

MLB51

Brand: Command access Pages: 2

TOUCHKEY

Brand: ERA Pages: 8

MLK1458BK

Brand: miseno Pages: 3