Summary of Contents for DOK-LOK RHR-600

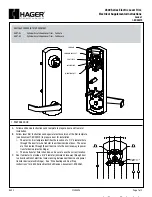

Page 6: ...6 RITE HITE RHR 600 DOK LOK Owner s Manual Figure 2 RHR 600 DOK LOK Features ...

Page 25: ...RITE HITE RHR 600 DOK LOK Owner s Manual 25 Notes ...

Page 33: ...RITE HITE RHR 600 DOK LOK Owner s Manual 33 Notes ...

Page 34: ...34 RITE HITE RHR 600 DOK LOK Owner s Manual Notes ...

Page 35: ......