Summary of Contents for SUPER DC INVERTER SERIES

Page 1: ...Contents i New Energy Requirement SUPER DC INVERTER SERIES Service Manual 2012 LFIS B 1211 ...

Page 2: ...ii General Information ...

Page 4: ......

Page 17: ...LFIS B 1211 Service Space Indoor Units 13 3 Service Space 1000mm 1000mm 1000mm 1000m m ...

Page 23: ...LFIS B 1211 Field Wiring Indoor Units 19 9 Field Wiring ...

Page 36: ...Duct Type LFIS B 1211 32 Indoor Units 10 Field Wiring ...

Page 40: ...Duct Type LFIS B 1211 36 Indoor Units 3 Service Space ...

Page 44: ...Field Wiring LFIS B 1211 40 Part 3 9 Field Wiring ...

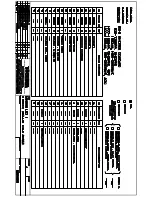

Page 50: ...Wiring Diagrams LFIS B 1211 46 Part 3 KOU 36HFN1 RRC4 ...

Page 100: ...Troubleshooting LFIS B 1211 96 Electrical Control System 2 4 2 3 Up down panel is not closed ...