Reviews:

No comments

Related manuals for DC 120VA

SS48055 LP

Brand: Patio Chef Pages: 34

EZT40050-P340

Brand: Fiesta Pages: 13

ProPress 2160

Brand: Villaware Pages: 10

PCC620

Brand: Porter-Cable Pages: 40

ADELAIDE PLANCHA TTL

Brand: Campingaz Pages: 69

PBL2022P

Brand: stayer Pages: 52

Grillerette Pro

Brand: TABLETOP Chefs Pages: 14

58828TS

Brand: Red Stone Pages: 25

Health Smart Grill Pro 42514

Brand: Gastroback Pages: 20

GRI 660

Brand: Gallet Pages: 52

DB 10

Brand: Metabo Pages: 52

112402

Brand: Princess Pages: 52

BG179A

Brand: Master Forge Pages: 38

XPH12T

Brand: Makita Pages: 11

NUEVO XT296ST

Brand: Makita Pages: 28

HP488D006

Brand: Makita Pages: 68

GBC983W-C

Brand: Uniflame Pages: 24

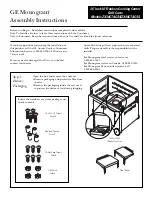

ZX48CTACSS

Brand: GE Pages: 4