V.2.1

◆

This guide book is for standard Ender-5 Plus only.

◆

Please plug the power cord into a three-hole

power jack.

◆

Detailed instructions are available in the TF card.

To be the Chief Evangelist

To make Top-quality 3D printer

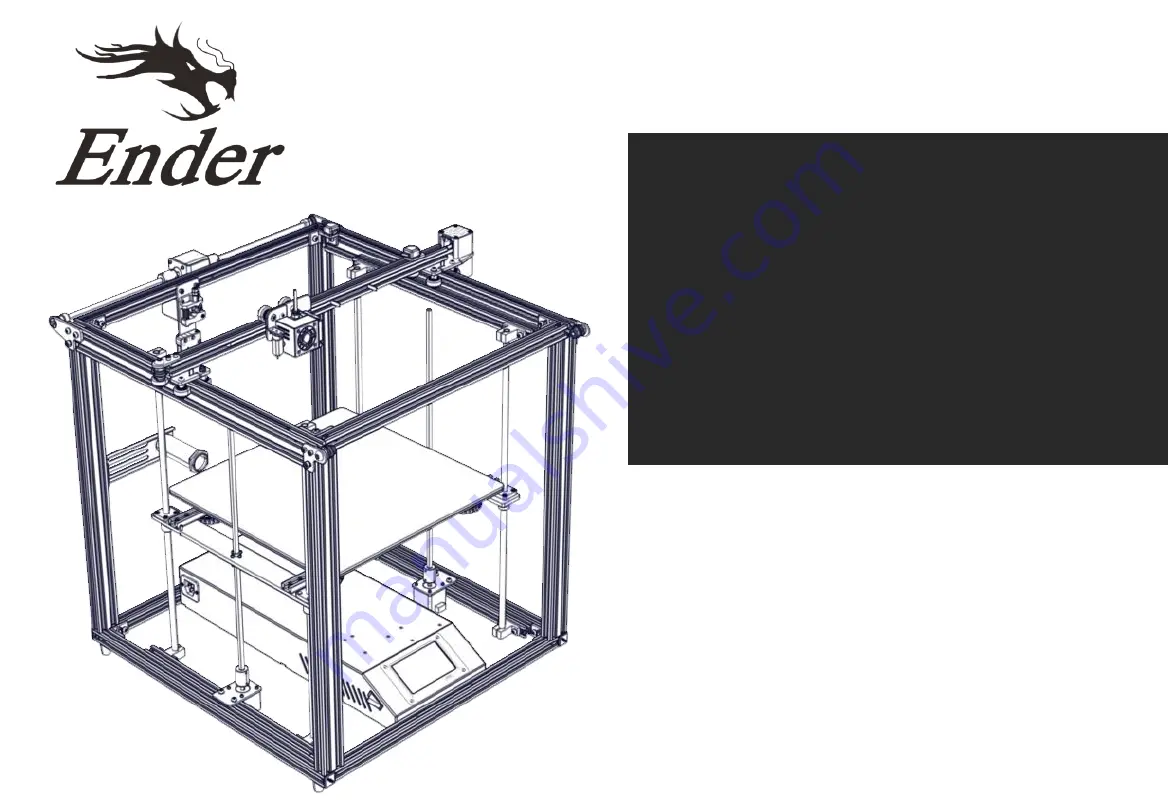

Ender-5 Plus Printer

Guide Book