Reviews:

No comments

Related manuals for CR Series

VLT VLA 31

Brand: Danfoss Pages: 4

White Rogers SureSwitch 49P11-843

Brand: Emerson Pages: 12

Liebert IntelliSlot IS-RELAY

Brand: Emerson Pages: 8

Alco Controls PS4 Series

Brand: Emerson Pages: 2

UPS2MB01

Brand: COQON Pages: 2

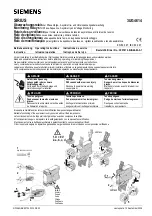

SIRIUS SRF2 Series

Brand: Siemens Pages: 3

SRC-8

Brand: Siemens Pages: 4

SIRIUS 3ZX1012-0RU11-1DA1

Brand: Siemens Pages: 4

SIRIUS S00

Brand: Siemens Pages: 7

SIRIUS 3UG4851 Series

Brand: Siemens Pages: 6

SIRIUS 3UG4841

Brand: Siemens Pages: 8

SIRIUS 3UG4513

Brand: Siemens Pages: 4

SIRIUS 3UG4501

Brand: Siemens Pages: 4

Sirius 3UG4651

Brand: Siemens Pages: 8

Sirius 3UG4614

Brand: Siemens Pages: 6

SIRIUS 3UG4631

Brand: Siemens Pages: 8

SIRIUS 3UG4624

Brand: Siemens Pages: 7

SIRIUS 3UG4641-1 Series

Brand: Siemens Pages: 8