INST20

18

_Model350_65-250

Rev.

11

/18

ZURN.COM.AU

ZURN WILKINS BACKFLOW

Double Check Valve Assembly

INSTALLATION & MAINTENANCE

MODEL 350 65-250mm

INSTALLATION INSTRUCTIONS

CAUTION:

Installation of Backflow Preventers must be performed

by qualified, licensed personnel. The installer should be sure

the proper device has been selected for the particular installa-

tion. Faulty installation could result in an improperly function-

ing device.

-

ZURN WILKINS Model 350 Double Check Valve assemblies are

for use on potable water lines where a health hazard does

exist in the event of a backflow situation.

-

Damage to the device could result wherever water hammer

and/or water thermal expansion could create excessive line

pressure. Where this could occur, shock arrestors, check valves

and/or pressure relief valves should be installed downstream

of the device.

-

If installation is in a pit or vault, the Backflow Preventer must

never be submerged in water because this could cause a

cross-connection. Make sure that the pit or vault always

remains dry by providing ample drainage.

1.

Before installing a Model 350 Backflow Preventer, flush the

line thoroughly to remove all debris, chips and other foreign

matter. If required, a strainer should be placed upstream of the

Backflow Preventer.

CAUTION:

Do not use a strainer in seldom

used emergency waterlines such as fire lines.

2.

Provide adequate space around the installed unit so that the

test cocks will be accessible for testing and servicing.

3.

Install valve at least 300mm above surrounding flood level.

4.

Always consult local codes for installation methods, approvals

and guidance.

5.

Resilient seated shutoff valves are required to be installed on

both the inlet and outlet of the device to make field testing

possible.

WARRANTY:

ZURN WILKINS Valves are guaranteed against defects of material or workmanship when used for the services recommended. Please

refer to the LWG Zurn/ Zurn Wilkins Product Warranty Statement for details.

PERFORMANCE

1

2

00kPa

60

Celsius

2400kPa

MODEL 350 FEATURES

Max. Working Water Pressure

Max. Working Temperature

Hydrostatic Test Pressure

End Connections

Flanged

WATERMARK

AS/NZS 2845.1

LIC. 1379

TYPE TESTED

AS/NZS 4020

LIC. 20111

STANDARDS COMPLIANCE

-

Australian Watermark (AS/NZS 2845.1) Approved Lic. 1379

-

Type Tested AS/NZS 4020 Lic. 20111

PLACING THE DEVICE IN SERVICE

1.

Start with both shut-off valves closed. Slowly open the inlet

shut-off valve until the backflow preventer is completely

pressurized.

2.

When the unit has been pressurized, vent any trapped air by

slightly opening each of the four test cocks.

3.

Slowly open the downstream shut-off valve. The Model 350

Double Check Valve assembly is now in service.

4.

After the Model 350 has been properly installed, test the device

(see “TEST PROCEDURES”). If the device fails the test, remove

the first and second check valves and thoroughly flush the

device. Clean rubber and seats of all debris and place unit back

in service.

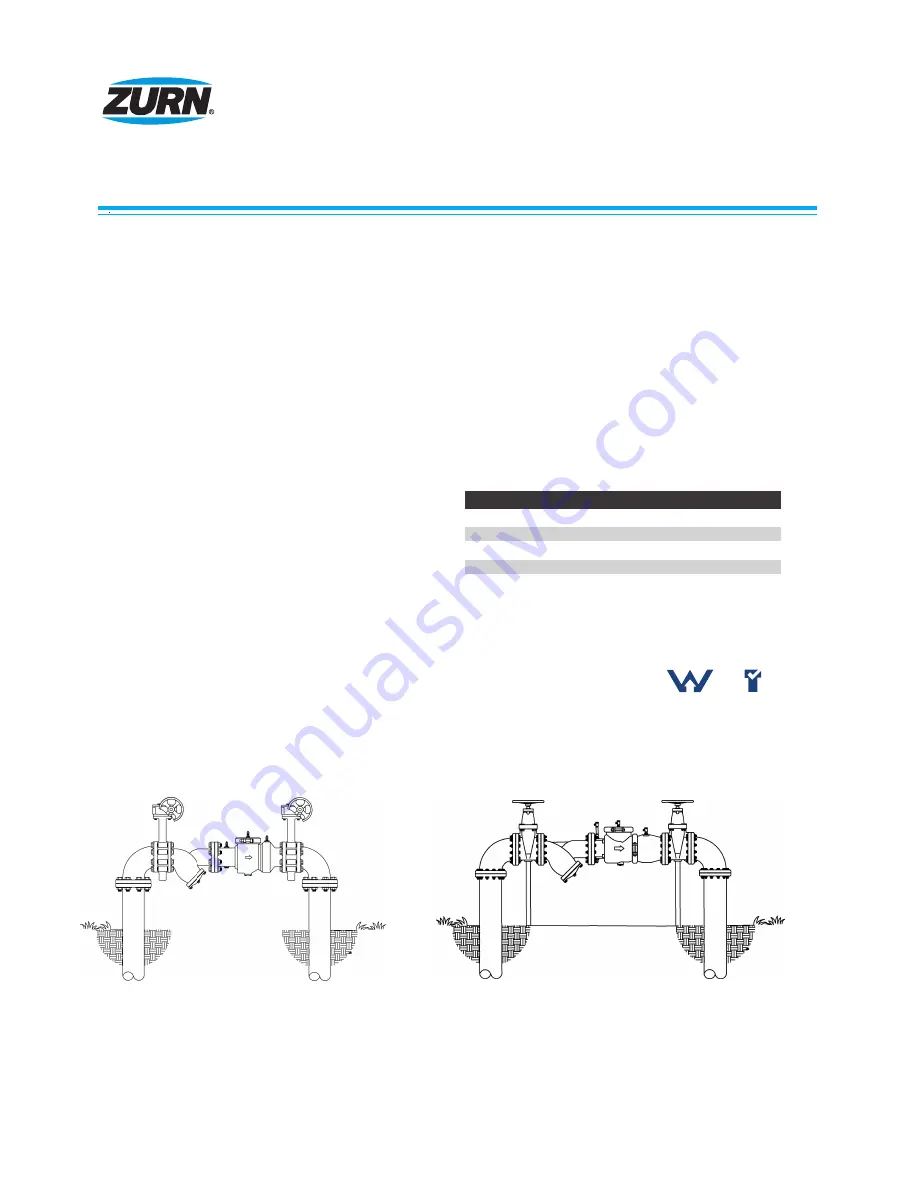

65, 80 & 150mm

200 & 250mm

OUTDOOR INSTALLATION:

The Model 350 Backflow Preventer may be installed outdoors only if the device is protected against

freezing conditions. Exposure to freezing conditions will result in improper function or damage to the device. The installation location

must be kept above 0°C. All the basic installation instructions apply.

DIRECTlON OF FLOW �

WILKINS MODEL 350

DIRECTlON OF FLOW �

WILKINS MODEL 350