Page 17

Page 16

EziSalt Saltwater Chlorinator | Installation Manual

1. Press

.

2. Use

to select “Reversing” then press .

3. Use

to select set hours then press .

4. Press

to exit.

<

-REVERSING

-HELP MENU

-LANGUAGE

MAIN MENU

<

INVERSION PERIOD

5 HOURS

REVERSING TIME

During reversal, chlorination is stopped for a few

minutes. No message is displayed on the screen.

Normal operation will resume after the reversal.

7.5 Slave Mode

NOTE

: It is not recommended to use Slave Mode

unless you have experience with multiple control

devices operating your pool.

Slave mode is applicable when the chlorinator is

connected to a third-party control device that uses

a chlorine/sanitiser sensor (such as an ORP sen-

sor). When in slave mode the chlorinator passes

control of turning chlorine production on/off to the

third party controller.

NOTE

:

Slave mode is not used when connected to

a general pool automation controller such

as AquaLink. It only applies to an external

controller that commands sanitiser output.

To enable this function, the third party controller

must be connected to the “slave” connection point

in the low voltage raceway see Table 5 and Figure

10 for wiring detail.

Boost and Low modes will remain operational from the

controller. However, SWC programs will be deactivated.

Chlorination output will be maintained at 100%.

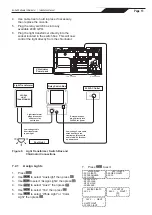

1. Connect the external controller at the slave

connection point in the low voltage raceway

see Table 3 and Figure 7 for wiring details.

2. Press

.

3. Use

to select “Slave Mode”

then press .

4. Use

to select “YES” or “NO” then press .

5. Press

to exit.

<

-SLAVE MODE

-REVERSING

-HELP MENU

-LANGUAGE

MAIN MENU

<

SLAVE MODE

ACTIVATE?

- YES

- NO

<

23:04 ON

SLAVE MODE

<

23:04 OFF

SLAVE MODE

Slave mode only controls the chlorination. Filtration

pump, AUX, lights and other functions are still valid.

Pressing

will take priority over Slave mode.

LOW / COVER / BOOST modes takes priority over

Slave mode

Section 8. Help Menu

The chlorinator will automatically notify you of any

problems by displaying error messages. To help

with the understanding of these messages, the

controller has a troubleshooting assistance menu

which gives the meanings and the action to take to

solve the problem.

1. Press

.

2. Use

to select “Help Menu” then press .

3. Use

to select the error message

then press .

4. The display will automatically scroll through

a certain number of suggested solutions to

explain what to do. Once automatic scrolling is

complete, the chlorinator automatically returns

to the “Troubleshooting” menu.

5. Press

to exit.