ZSSC5101

Evaluation Kit Description

Kit Description

April 17, 2015

© 2015 Zentrum Mikroelektronik Dresden AG

— Rev. 1.00

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the

prior written consent of the copyright owner. The information furnished in this publication is subject to changes without notice.

18 of 25

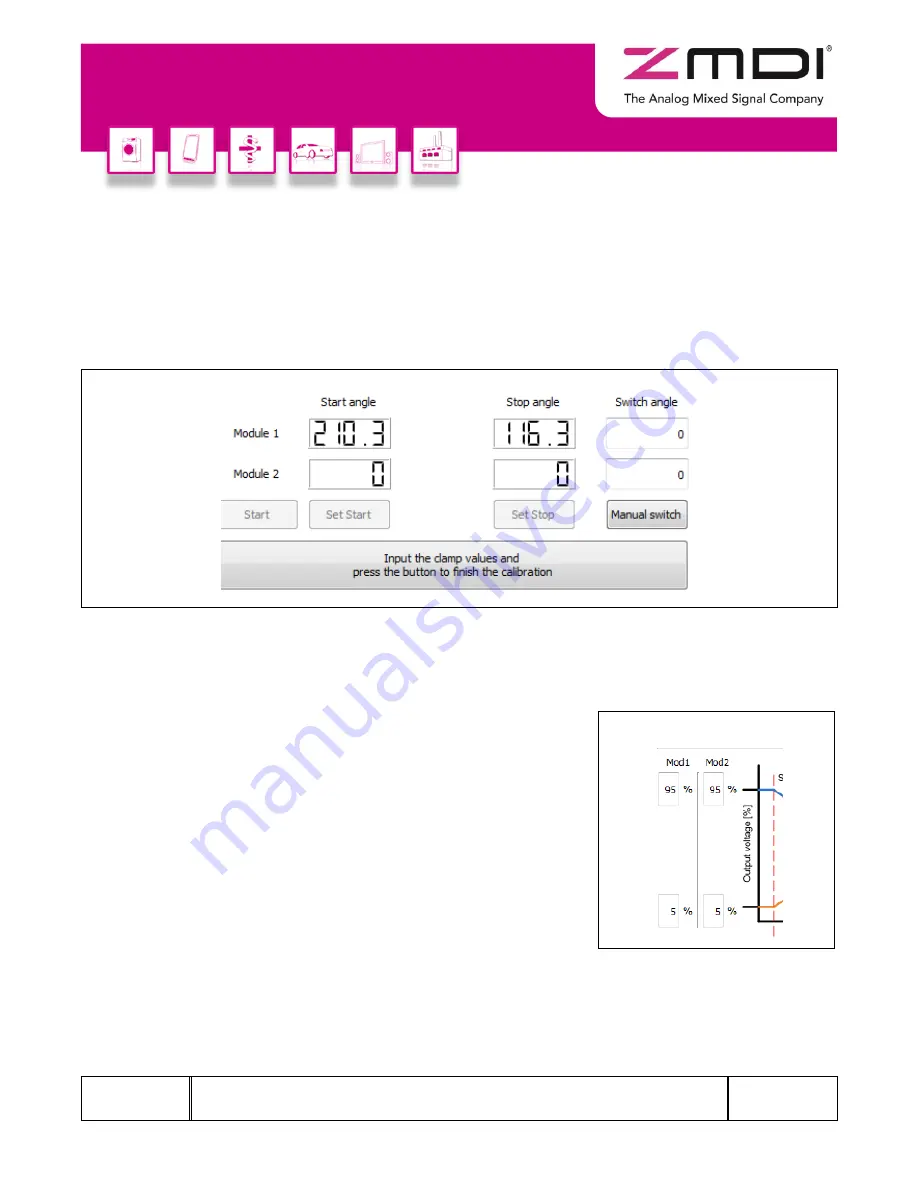

1. Click the

“Start” button on the “Angle Calibration” tab and wait until the “Set Start” button becomes active.

2. Move the magnet to the start position (note that this is the maximum clockwise position when looking at

t

he sensor from the top). Click “Set Start.” This stores the start position, and then the “Set Stop” button

becomes active.

3. Rotate the magnet to the stop position (when looking at the sensor from the top, rotate the magnet

counterclockwise to the stop p

osition) and click “Set Stop.” This stores the stop position.

Figure 4.10

Setting the Angle Range with the “Angle Calibration” Tab

4. Optional: The switch angle, which is the angular position where the analog output returns from Vout,max

to Vout, min, can be manually entered

for each module in the “Switch angle” entry fields. Then click

“Manual switch” to confirm the entry, which stores the value in EEPROM. If no value is entered, it will be

calculated automatically.

5. Optional: Enter the minimum and maximum clamping values at the

two mechanical stop positions as percentages of VDD in the entry

fields adjacent to the graph in the upper left section of the tab.

Alternatively, the default values that are already displayed can be

used. See Figure 4.11, which illustrates the example default values

Vmin = 5% VDD and Vmax = 95% VDD.

6. To complete the angle calibration, click the large button at the

bottom

of the tab, which has the label “Input the clamp values and

press the button to fin

ish the calibration.” (See Figure 4.10.) When

the angle programming is completed, this button becomes grey

and its label changes to “Done.”

Figure 4.11 Clamping Values