ES3, ES4 & ES6 Instructions. Issue: No. 2

Page 9

February / 2012

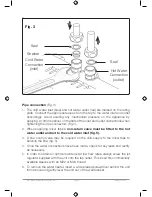

Seal

Seal

Hot Water

Connection

(outlet)

Strainer

Cold Water

Connection

(inlet)

Fig. 3

Pipe connection

(Fig. 3)

1. The cold water inlet (blue) and hot water outlet (red) are marked on the rating

plate. Connect the appropriate pipes from the tap to the water inlet and outlet

accordingly. Avoid exerting any mechanical pressure on the appliance by

applying a 13mm spanner on the flats of the inlet and outlet connections when

tightening the pipe connectors (Fig.3).

2. When supplying mixer taps a

non-return valve must be fitted to the hot

water outlet and not to the cold water inlet (fig. 5).

3. A flow control valve may be required on the cold supply to the mixer taps to

balance the flow (fig. 5).

4. Once the water connections have been made, check for any leaks and rectify

as necessary.

5. In order to obtain an optimum water jet at low flow rates, always screw the jet

regulator supplied with the unit onto the tap outlet. This insert fits commercially

available sleeves with an M22 or M24 thread.

6. To remove the water heater, insert a wide bladed screwdriver behind the unit

from above and gently lever the unit out of the wall bracket.