•

Metal screwed-connections are not permitted in plastic housing parts because there is no potential

equalization.

•

Care must be taken to avoid direct radiation from the sun!

•

The device is designed for vertical installation (bottom cable inlet). A horizontal or reclined installa-

tion is only permissible after technical release of the manufacturer!

•

Be sure to observe proper heat dissipation (see Technical data, heat dissipation).

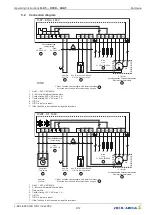

4.2

Minimum space requirement

In order to ensure suf

fi

cient ventilation of the device, clearance on all sides of at least 50 mm has to

be maintained to the housing walls, switch cabinet doors, wiring ducts, etc. The same clearance

applies to the installation of several devices next to each other.

When installing several devices on top of each other, the danger of reciprocal heating exists. This

layout is only then permissible when the air suctioned from the upper unit does not become warmer

than the permissible ambient temperature (see Technical data). I.e., a correspondingly larger clear-

ance or thermal shielding is required.

4.3

Mains connection

Power from the mains is connected to terminals: PE, L1, L2, L3 and N (only for 400 V version). Here, it

must be strictly observed that the mains voltage lies within the allowable tolerance speci

fi

cations (see

Technical data and nameplate af

fi

xed to the side).

The mains voltage must comply with the EN 50160 quality characteristics and the de

fi

ned standard

voltages in IEC 60038!

Danger due to electric current

•

The internal transformer is not short-circuit-proof, note: maximum size of line fuse detailed in the

operating instructions. When using automatic circuit breakers, you must use a 3-poled type with

“

C

”

characteristics.

•

To prevent transformer overloading, exclude two-phased conductance by taking measures at the

customer location. Alternative to phase monitoring, a motor overload protector with phase-failure

sensitivity can be used as the backup fuse. Set it to the rated current of the transformer-induced

control device.

4.4

Motor connection

The motor leads are connected to the terminals: PE, U, V, W. Several fans can be connected to the

controller-the maximum total current of all motors must not exceed the current rating for the controller.

Motor protection via connection of TB thermostatic switches (not suitable for PTC thermistors). When

the thermostatic switches are triggered (motor fault), the device switches off. Restart is performed

once the drive has cooled down either by switching the mains voltage off and on again (after approx. 2

minutes) or via the switch.

Attention!

If multiple motors are connected, connect thermostatic switches to the TB-TB (TK-TK) terminals in

series.

Operating Instructions

R-DT-.., RTRD.., RUDT..

Installation

L-BAL-E285-GB 1907 Index 002

Part.-No.

6/12