Insulation fault

A chassis leakage above the programmed threshold has been

detected. (May indicate an insulation fault, or even water inside

a DC motor.)

Low 12V battery

The voltage of the 12V auxiliary battery (power supply for the

EVMS) has dropped below the programmed threshold. May

indicate a weak battery or faulty DC/DC converter.

Precharge failed

Displayed if an error is detected during the precharge sequence,

either failing to start (usually a wiring fault) or taking too long to

finish (usually an unexpected load “downstream” from the main

contactor). The startup sequence is cancelled automatically.

Contactor seized

If using contactors with auxiliary switches and a discrepancy

is detected (contactor closed when it should be open, or vice

versa), this error will be displayed.

BMS - comms error

If the EVMS Core hasn’t received data from a BMS module for

a while (about 1 second), this error will appear and the traction

circuit will be shut down for safety.

Comms error to Core

If the EVMS Monitor hasn’t received data from the Core for

more than 1 second, this error will appear. Most commonly this

is due to a wiring fault on the CAN bus.

Peukert’s Effect

All batteries exhibit a reduction in available capacity depending on how fast they

are discharged, known as Peukert’s Effect. For most lithium batteries in EVs the effect is

negligible, but for lead acid batteries it can be quite significant. The EVMS can automatically

compensate for Peukert’s Effect for different battery types. The Peukert’s Exponent is modified

in the EVMS Core settings to suit your battery type as follows:

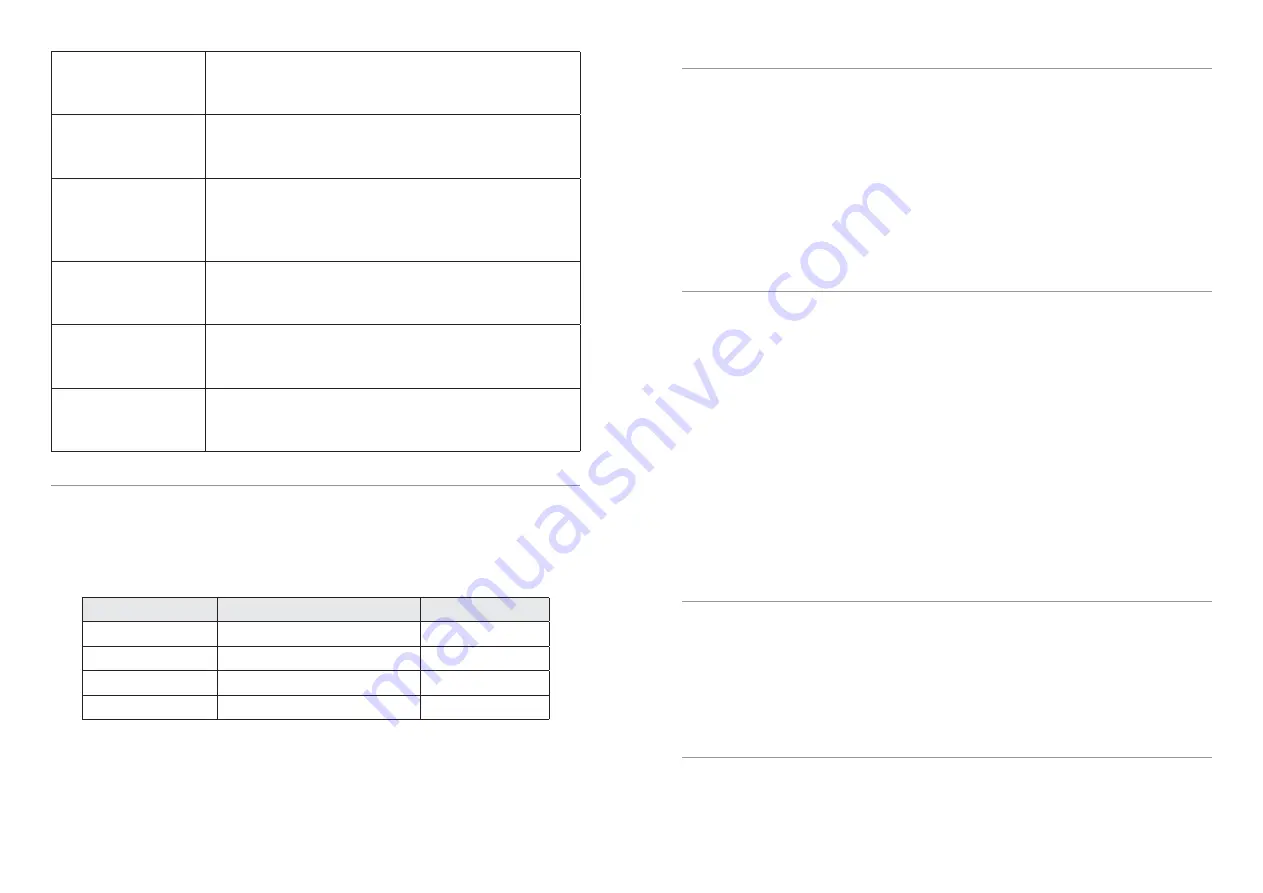

Peukert’s Exponent

Chemistry and type

Capacity at 1C

1.0

Lithium: LiCo, LiMn, LiFePO4

100% of C20

1.1

Lead acid: AGM

75% of C20

1.2

Lead acid: Gel cell

55% of C20

1.3

Lead acid: Flooded

40% of C20

Lead acid batteries have a capacity rated at C20 – that is, how many amp-hours the battery

can supply if discharged over a 20 hour period. When configuring the pack capacity in the

EVMS, use the C20 rate. Lithium batteries are typically rated at 1C, but they exhibit minimal

Peukert’s Effect so it is close enough to their C20 rate.

State of Charge drift and synchronisation

The EVMS uses a hall effect sensor for current measurement and, by integrating current over

time, calculating battery state of charge. While offering easy installation, safe isolation and

good linearity, hall effect current sensors can exhibit a small amount of zero-point drift and

inaccuracy at low currents, which can accumulate over time causing the reported SoC to

differ from the actual SoC. To mitigate this, the EVMS includes a system to automatically

resynchronise the SoC at the end of any full charge cycle, via programmable “Full voltage”

setting. Ideally, set this to a volt or two below the peak charge voltage of your charger. This

way at the end of each full charge, the SoC will be synchronised back to 100%.

The SoC can also be manually reset to 100% via the Options menu of the EVMS Monitor.

Stationary Applications

The EVMS configuration includes a setting for Stationary Mode, intended for use in battery

backup and off-grid power applications. In this mode, the Key input enables both Main

Contactor and Charge Enable outputs concurrently. An undervoltage cell will disable the

Main Contactor output (to remove any loads on the battery) and an overvoltage cell will

disable the Charge Enable output (to disable any charging sources). In both cases the outputs

are re-enabled once the voltage has recovered by 0.4V (i.e there is ±0.2V hysteresis around

the configured thresholds).

In Stationary Mode, the Charge Sense input is no longer used, typically the Aux Ctr output

will not be used, and precharging is not supported.

For LiFePO4, we recommend an undervoltage threshold of 2.8V (which results in 2.6V cutout

and 3.0V re-enabling for any loads on the battery), and an overvoltage threshold of 3.6V (for

3.8V charger cutout and 3.4V re-enabling). These thresholds give about 1% hysteresis on the

battery state of charge to avoid rapid cycling of the charger or outputs.

Use with system voltages above 320VDC nominal

The EVMS Core’s internal voltage measurement and isolation monitoring circuit has an

absolute maximum voltage rating of 400VDC, making it suitable for nominal battery pack

voltages up to about 320VDC. The Core may be used with higher voltages, but the

HV+

,

HV-

and

Main Ctr-

connections must be omitted. Precharging and isolation monitoring no longer

supported, and system voltage is instead calculated from the sum of all cells connected to

BMS modules.

Leakage / insulation fault detection

The EVMS Core has an internal high resistance connection (200Kohm) between the traction

circuit and the vehicle chassis. By monitoring microamps of current flowing across this

resistor, the EVMS Core can detect if the isolation between traction circuit and the vehicle

chassis is compromised, such as from damaged wiring insulation, excessive carbon buildup