ZHD 2500-130/150

52

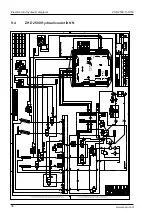

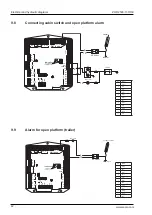

Connection unit

www.zepro.com

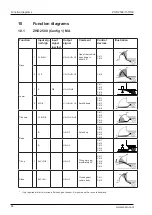

Fault codes

Identification

Code 1 Code 2 Code

3

Information

Other

L

Low battery voltage

07-35

Voltage measured

H

High battery voltage

07-35

Voltage measured

E

Control device

locked

1

Fixed control device 1 (incl. two-

hand button 2h1 if they are moni-

tored)

2

Fixed control device 2 (incl. two-

hand button 2h2 if they are moni-

tored)

3

Radio control device, external

4

Coil control device

5

Truck slider control device

6

Radio control device, internal

module

7

CS (cabin switch)

Segment

Segments B, C, E or X are il-

luminated depending on which

button signal has locked the

control device.

B

C

E

X

In

Out

F

Output short-circuit-

ed/high current

0-9

Which output has short-circuited/

has high current. Fault code is

reset automatically if the function

in question is running (function

verified).

1-7 U0-U7, dis-

played only

a f t e r t h e

respective

output/function

has been ac-

tive.

8 Control power

9 Sensor power

Output not connect-

ed/cable breakdown

0-7

Which output is not connected/

has cable breakdown. Fault

code is reset automatically if the

function in question is running

(function verified).

Displayed only af-

ter the respective

output U0-U7 has

been active.

A

Internal fault

0-

Any measurement faults are reg-

istered by the system.

Contact support

if the lift does not

function.

All fault codes can be reset manually by switching On/Off the CS (cabin switch). Fault codes

F0-F7 and U0-U7 are reset automatically if the function in question is running (function verified).

Fault codes L and H are reset automatically if the battery voltage becomes correct. Fault code E

is reset automatically if the control system has not received any signal from the relevant control

device for 6 minutes.

Example of sequence of fault codes:

Output No. 3 short-circuited.