14

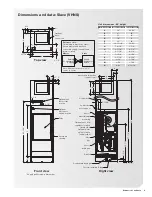

Cabinet and

riser installation

Riser expansion

Generally, in medium to high-rise

buildings, allowances must be made

for pipe expansion. In applications

supplemented with factory (or field)

supplied between-the-floor riser

extensions, assemble and install

extensions before installing cabinet.

All riser modifications necessitated

by variations in floor-to-floor

dimensions, including cutting off

or extending risers, is the sole

responsibility of the installing

contractor.

Additional expansion compensation

must be made in the riser system,

in the field, where movement is

expected to exceed the factory

allowances. The “Allowable Riser

Lengths Between System Expansion

Loops” chart on the opposite

page displays the expansion

characteristics of risers compared to

water temperature differential.

Riser connections

Install cabinet with risers as

follows:

■

■

Move cabinet into position.

Caution:

Keep risers off the

floor while moving the cabinet.

■

■

Do not carry units by risers.

■

■

Be sure that all the copper

fittings are clean and free of

dirt. Raise the cabinet upright

and lower it into the riser from

the floor below.

Note:

The top of each riser

is equipped with a 3" deep

swaged connection. There

is sufficient extension at the

bottom to allow insertion of

approximately 2" of the riser

into the swaged top of the riser

below.

■

■

Center risers in the pipe chase

and shim the cabinet level.

Plumb risers in two planes to

assure proper unit operation

and condensate drainage.

■

■

Attach the cabinet assembly

to the floor and the building

structure on at least two sides

using sheet metal angles (field

provided). A field provided

base vibration dampening pad

can be used to help eliminate

transfer of any vibration to

the structure. If vibration

dampening pads are used,

some rough-in dimensional

changes will need to be

considered before installation

due to style and thickness of

the pads. Additional anchorage

can be provided by installing

brackets at the top of the

cabinet (field provided).

■

■

Do not

attach drywall studs to

the equipment cabinet.

■

■

When all units on a riser are

anchored into place, complete

riser joints as follows:

■

■

Verify that all riser joints are

vertically aligned and that

risers penetrate at least 1"

into the swaged joint of the

riser below.

Do not

let riser

joint bottom out.

■

■

Braze riser joints with a

high-temperature alloy

using proper Phos-copper

of Silfos. Soft solder 50-50,

60-40, 85-15, or 95-5 or low

temperature alloys are not

suitable riser weld materials.

■

■

Anchor built-in risers to

the building structure with

at least one contact point.

To accommodate vertical

expansion and contraction

do not

fasten risers rigidly

within the unit.

■

■

Verify that unit shut-off

valves are closed.

Do not

open valves

until the system

has been cleaned and

flushed.

■

■

Flush system, refer to

the System Cleaning and

Flushing Section on page

24 of this manual for more

information.

■

■

Install vents in piping loop,

as required, to bleed the

system of air accumulated

during installation.

Notes

■

■

Riser assemblies are designed to

accommodate a maximum of 1-1/8"

expansion and contraction up to a total

movement of 2-1/4".

■

■

If the total calculated rise expansion exceeds

2-1/4", expansion devices must be used

(field provided).