23

Commissioning

When the hob has been fully installed it will be necessary

to check the minimum flame setting. To do this, follow

the procedure below.

- Turn the gas tap to the MAX position and ignite.

- Set the gas tap to the MIN flame position then turn

the control knob from MIN to MAX several times. If

the flame is unstable or is extinguished follow the

procedure below.

F

Procedure:

- Re-ignite the burner and set to MIN.

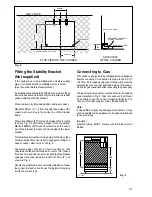

- Remove the control knob. The adjustment screw is

located down the centre of the gas tap control shaft

or on the lower right hand side of the shaft (see

diagram).

- To adjust, use a thin bladed screwdriver and turn the

adjustment screw until the flame is steady and does

not extinguish, when the knob is turned from MIN to

MAX. Repeat this procedure for all burners.

F

Pressure Testing

- Remove left hand pan support and front left burner

cap and crown.

- Fit manometer tube over the injector.

- Turn on the burner gas supply and ignite another burner

supply.

- The pressure reading should be nominally 20mbar

and must be between 17 mbar and 25mbar.

- Turn off the burner supplies.

Conversion from Natural Gas to LPG

It is important to note that this model is designed for use

with natural gas but can be converted for use with butane

or propane gas providing the correct injectors are fitted

and the gas rate is adjusted to suit.

Method

Ensure that the gas taps are in the 'OFF' position

Isolate the hob from the electricity supply

Remove all pan supports, burner caps, rings, crowns

and control knobs.

With the aid of a 7mm box spanner the burner injectors

can then be unscrewed and replaced by the

appropriate LPG injectors (see Technical Data).

To adjust the gas rate

With the aid of a thin bladed screwdriver completely

tighten down the by pass adjustment screw, which is

located down the centre of the gas tap control shaft.

Upon completion stick the replacement rating plate on

the under side of the hob.

IMPORTANT

The replacement/conversion of the gas hob should only

be undertaken by a competent person

a)

Minimum adjustment screw

b)

Tap

FO 1032

a