YZ Systems, Inc. • 3101 Pollok Drive • Conroe, Texas • USA • 77303 • P: 936.788.5593 • F: 936.788.5720

Page 37

DP-2010FU ver.04202004

SSSSS

ECTION

ECTION

ECTION

ECTION

ECTION

10:

10:

10:

10:

10: S

S

S

S

S

Y

YY

Y

YSTEM

STEM

STEM

STEM

STEM

M

M

M

M

M

AINTEN

AINTEN

AINTEN

AINTEN

AINTENANCE

ANCE

ANCE

ANCE

ANCE

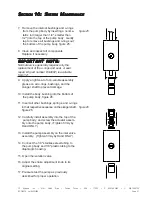

7. Remove the internal bushings and o-rings

from the pump body by inserting a nonme-

tallic rod (larger than 1/4", smaller than

1/2") into the top of the pump body. Gently

tap to remove all bushings and o-rings out

the bottom of the pump body, figure 25.

8. Clean and inspect all components.

Replace if necessary.

9. Apply a light coat of non-soluble assembly

grease on all o-rings, bushings, and the

plunger shaft to prevent damage.

10. Install the body bushing into the bottom of

the pump body, figure 26.

11. Insert all other bushings, springs, and o-rings

in their respective sequence on the plunger shaft,

figure 26.

12. Carefully install assembly into the top of the

pump body, and screw the actuator assem-

bly onto the pump body. (Tighten firmly by

Hand ONLY)

13. Install the pump assembly on the inlet valve

assembly. (Tighten firmly by Hand ONLY).

14. Connect the 1/8" stainless steel tubing to

the pump body and 1/8" plastic tubing to the

diaphragm housing.

15. Open the isolation valve.

16. Adjust the stroke adjustment knob to its

original setting.

17. Pressure test the pump as previously

described for proper operation.

11.2 j

11.2 k

11.2 g

figure 25

figure 26

IMPOR

IMPOR

IMPOR

IMPOR

IMPORTTTTTANT NO

ANT NO

ANT NO

ANT NO

ANT NOTE:

TE:

TE:

TE:

TE:

Normal service generally requires only the

replacement of the o-rings and seal. A seal

repair kit (part number D3-0002) is available

from YZ.