6

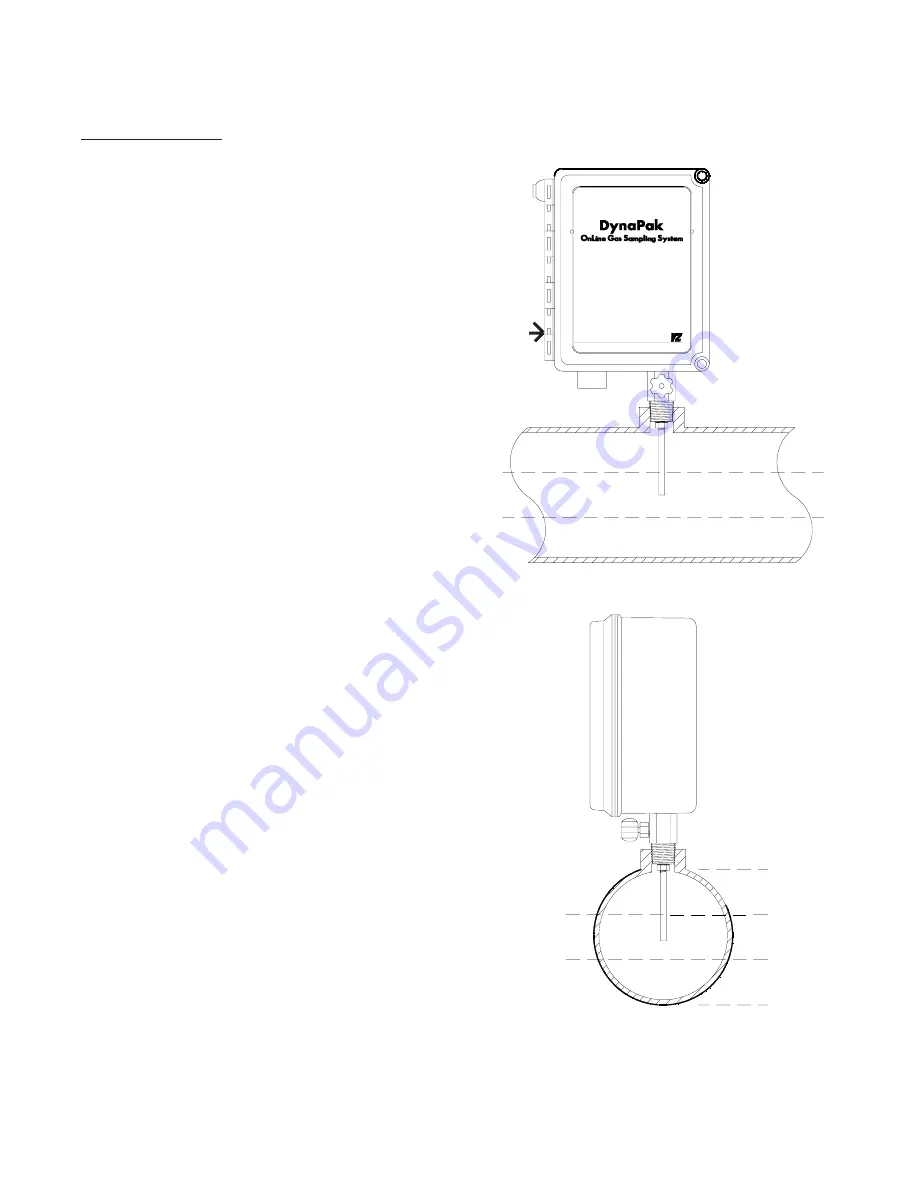

5.1 DynaPak 2010

a. The DynaPak 2010 requires a 3/4" FNPT

pipeline connection.

b. The DynaPak 2010 sampler should be

mounted vertically in a horizontal run of the

pipeline.

c. The end of the sampler probe should penetrate

the center 1/3rd of the pipeline.

d. The end of the sample probe should be cut

parallel to the pipeline.

e. Before applying pipeline pressure to the

DynaPak 2010, ensure that the isolation valve and

purge valve are closed.

f. After pipeline pressure has been applied to the

sampler, check the probe body/pipeline connection

using a liquid leak detector.

g. 1/4" stainless steel tubing must be connected

from a source of supply actuation gas with a

minimum pressure of 65 psig to the external gas

supply connection for the Filter Regulator located

on the left side of the sampler enclosure.

CAUTION

Incorrect operation of valves (over tightening) can

result in damage to the valve components (isola-

tion valve bonnet assembly) which might result in

the valve stem being screwed out of the probe

body. This of course results in product at pipeline

pressure being vented continually through this port

until this section of the pipeline is shut in. Be aware

of the following procedures and information.

· DynaPak valves are of soft seat

design and should only be closed

or opened with fingers. No

wrenches should ever be used.

· If a valve will not seal off with

finger tight operation the valve

should have maintenance

performed to allow proper

operation of the valve.

5. System Installation

Center 1/3

1/3

1/3

1/3

Center 1/3

1/3

1/3

1/3

Maximum Pipeline Pressure 1500 psig.

E x t e r n a l

Gas Supply

Connection