6

Unconditioned Spaces

All duct work passing through unconditioned space must

be properly insulated to minimize duct losses and prevent

condensation. Use insulation with an outer vapor barrier.

Refer to local codes for insulation material requirements.

Acoustical Duct Work

•

Certain installations may require the use of acoustical

lining inside the supply duct work. Acoustical insulation

must be in accordance with the current revision of the

Sheet Metal and Air Conditioning Contractors National

Association (SMACNA) application standard for duct

liners. Duct lining must be UL classified batts or blankets

with a fire hazard classification of FHC-25/50 or less.

• Fiber duct work may be used in place of internal duct

liners if the fiber duct work is in accordance with the

current revision of the SMACNA construction standard

on fibrous glass ducts. Fibrous duct work and internal

acoustical lining must be NFPA Class 1 air ducts when

tested per UL Standard 181 for Class 1 ducts.

•

Damping ducts, flexible vibration isolators, or pleated

media-style filters on the return air inlet of the electric

furnace may be used to reduce the transmission of

equipment noise eminating from the electric furnace.

These treatments can produce a quieter installation,

particularly in the heated space. However, they can

increase the pressure drop in the duct system. Care

must be taken to maintain the proper maximum pressure

rise across the electric furnace, temperature rise and

flow rate. This may mean increasing the duct size and/

or reducing the blower speed. These treatments must

be constructed and installed in accordance with NFPA

and SMACNA construction standards. Consult with

local codes for special requirements. For best sound

performance, be sure to install all the needed gaskets

and grommets around penetrations into the electric

furnace, such as for electrical wiring.

Air Filters

B5BV series electric furnaces are not supplied with an

air filter when shipped from the factory. The installer must

provide a high velocity filter that is appropriately sized

to the return air duct opening or filter rack located in the

bottom of the unit. Accessing the filter does not require

tools and can be removed from the front of the unit by

removing the filter door. See Unit Maintenance (page 12)

for filter sizes and installation information.

WARNING:

Never operate the electric furnace without a

filter or with doors removed. Dust and lint can

build up on internal components, resulting

in loss of efficiency, equipment damage, and

possible fire.

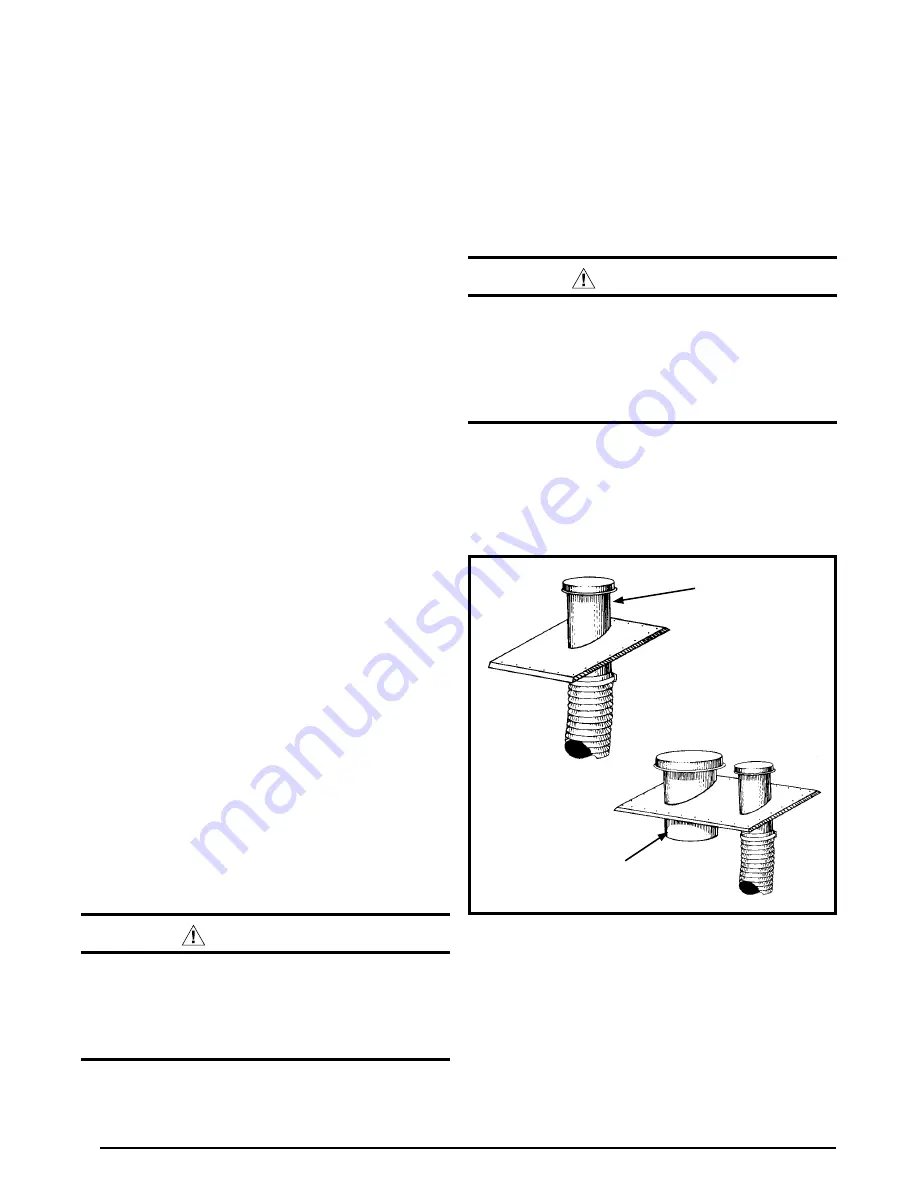

VentilAire III

VentilAire IV

Figure 2. VentilAire III & IV

Ventilaire III or IV Air Quality Package (Accessory)

The B5BV electric furnace has a cutout on each side of

the cabinet for ventialtion air. The Ventilaire air quality

packages introduce outdoor air into the living space during

furnace blower operation. The VentilAire IV also serves to

exhaust moist and/or hot air from the attic space. These

packages meet the ventilation requirements as outlined

in H.U.D. Standard Part 3280.103 (b) (2). See Figure 2

for typical installation.

CAUTION:

MAINTAIN 2 1/2” MINIMUM CLEARANCE

BETWEEN FLUE PIPE AND FLEX DUCT. FAILURE

TO COMPLY WITh ThIS RESTRICTION COULD

CAUSE EQUIPMENT DAMAGE. VENTILAIRE III

ILLUSTRATED OThER LISTED VARIATIONS

AVAILABLE. ChECK WITh MANUFACTURER.

Use adaptor (part number 914427) with Ventilaire III or

IV to supply the proper amount of ventilation air. The

VentilAire connections must be made for the system to

conform to H.U.D. rules. Do not leave disconnected after

servicing or adding A/C to the system. Complete installation

instructions are supplied with each air quality package.