5.4.

Tilt-only interface

5.4.1.

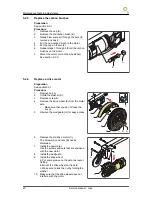

Replace the Tilt Actuator (Tilt-only Interface)

Preparation

1.

Set the interface in the maximum tilted position for easy access.

2.

Prepare the wheelchair for maintenance. See section

5.1.

3.

Disconnect the interface cables from the controller.

Procedure

1.

Make sure that the interface is kept in the

tilted position. For instance by placing a

support.

2.

Disconnect the actuator cable.

3.

Remove the circlips (B) from the pivot (C) at

both ends of the actuator (A).

4.

WARNING!

Make sure that the tilt

mechanism is supported

safely.

Remove the old actuator.

5.

Put the new actuator into the tilt

mechanism.

6.

Connect the actuator cable.

7.

Make sure that the actuator cable can follow

the movement of the mechanism but that

the cable does not get jammed by the

mechanism.

8.

Check the functionality of the actuator.

A

C B

5.5.

Tilt + lift interface

5.5.1.

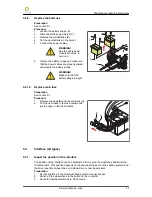

Replace the tilt actuator

Preparation

1.

Set the interface in the maximum tilted position for easy access.

2.

Prepare the wheelchair for maintenance. See section

5.1.

3.

Disconnect the interface cables from the controller.

Procedure

1.

Make sure that the interface is kept in the

tilted position. For instance by placing a

support.

2.

Disconnect the actuator cable.

3.

WARNING!

Make sure that the tilt

mechanism is supported

safely.

Remove the circlips (B) at the pivot (C) at

the end of the actuator.

4.

Remove the old actuator (A).

5.

Put the new actuator into the tilt

mechanism.

6.

Connect the actuator cable.

7.

Make sure that the actuator cable can follow

the movement of the mechanism but that

B

A

C

D

Maintenance tasks & adjustments

Service manual - Luca

25