5567611-BIM-B-1218

64

Johnson Controls Ducted Systems

If there is a call for dehumidification and no call for cooling, the

unit automatically reverts back to the normal hot gas reheat

mode only allowing refrigerant stage one to run in reheat mode

and refrigerant stage two remains off.

If there is a call for dehumidification and a call for cooling, the

unit remains in the alternate hot gas reheat mode allowing

refrigerant stage one to run in hot gas reheat or

dehumidification mode and refrigerant stage two runs in

cooling.

Electric heating sequence of operations

The following sequence describes the operation of the electric

heat section.

Two-stage heating:

a. When there is a call for first stage heat by the thermostat,

the heater relay (RA) is energized. After completing the

specified fan on delay for heating, the UCB energizes the

blower motor. If the second stage of heat is required,

heater relay (RB) is energized. After completing the

specified fan on delay for heating, the UCB energizes the

blower motor.

b The thermostat cycles the electric heat to satisfy the

heating requirements of the conditioned space.

Electric heat operation errors

Temperature limit

If the UCB senses zero volts from the high temperature limit,

the indoor blower motor is immediately energized.

This limit is monitored regardless of unit operation status, that

is, the limit is monitored at all times.

If the temperature limit opens three times within one hour, it

locks on the indoor blower.

Safety controls

The UCB monitors the temperature limit switch of electric heat

units.

The control circuit includes the following safety controls:

Limit switch

The limit switch (LS) is located inside the heater compartment

and is set to open at the temperature indicated in Table 26,

on page 64. It resets automatically.

The limit switch operates when a high temperature condition

caused by inadequate supply air flow occurs. This shuts down

the heater and energizes the blower.

Reset

Reset removes the call for heating by lowering the thermostat

setting lower than the conditioned space temperature.

Electric heat anticipator setpoints

The anticipator setpoint must be correct. Too high of a setting

results in longer heat cycles and a greater temperature swing in

the conditioned space. Reducing the value below the correct

setpoint gives shorter ON cycles and may result in the lowering

of the temperature within the conditioned space. See Table 27

for the required electric heat anticipator setting.

Gas heating sequence of operations

When the thermostat calls for the first stage of heating, the low-

voltage control circuit from R to W1 is completed. A call for heat

passes through the UCB to the ignition control board (ICB). The

UCB monitors the W1 call and acts on any call for heat by

monitoring the gas valve (GV). When voltage is sensed at the

GV, the UCB initiates the fan on delay for heating, energizing

the indoor blower when the specified delay has elapsed.

When the thermostat is satisfied, heating calls are ceased. The

GV is immediately closed. The blower is de-energized after the

fan off delay for heating has elapsed. The draft motor performs

a 30-second post purge.

Ignition control board

First stage of heating

When the ICB receives a call for first stage of heating, “W1,” the

draft motor is energized. Once the draft motor has been proven,

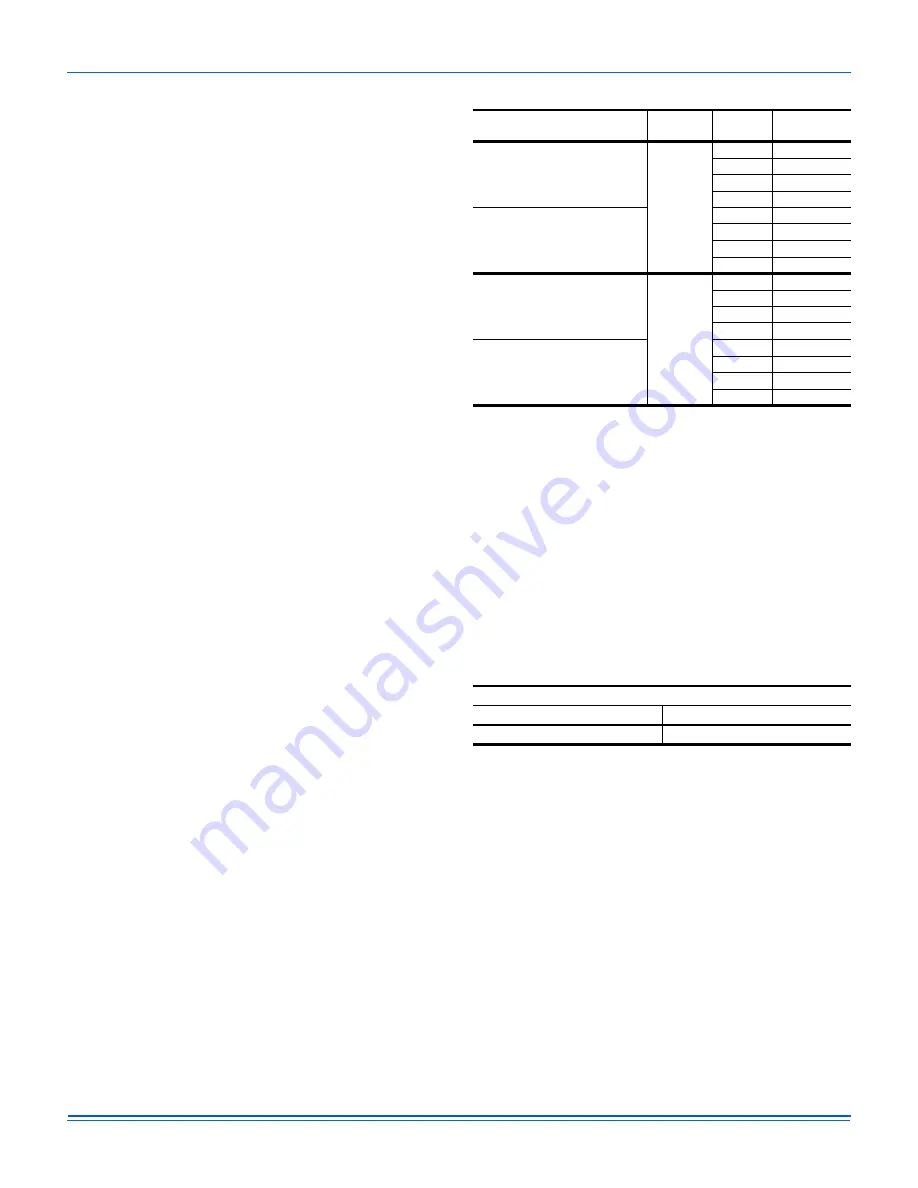

Table 26: Electric heat limit setting

Unit (tons)

Voltage

Heater

kW

Limit switch

opens °F

ZV-06 (6.5)

ZV-07 (7.5)

ZV-08 (8.5)

208/230

9

150

18

150

24

150

36

150

ZV-10 (10)

ZV-12 (12)

18

150

24

150

36

150

54

130

ZV-06 (6.5)

ZV-07 (7.5)

ZV-08 (8.5)

480

9

150

18

150

24

150

36

150

ZV-10 (10)

ZV-12 (12)

18

150

24

150

36

150

54

130

Table 27: Electric heat anticipator setpoints

Setting, Amps

W1

W2

0.13

0.1