FORM 155.19-EG3 (1011)

5

JOHNSON CONTROLS

Ratings

Computerized Performance Ratings

Each chiller selection is custom-matched to meet the

individual application requirements. It is not practical to

provide tabulated information for all possible combina

-

tions. Computerized performance ratings are available

through each Johnson Controls sales office.

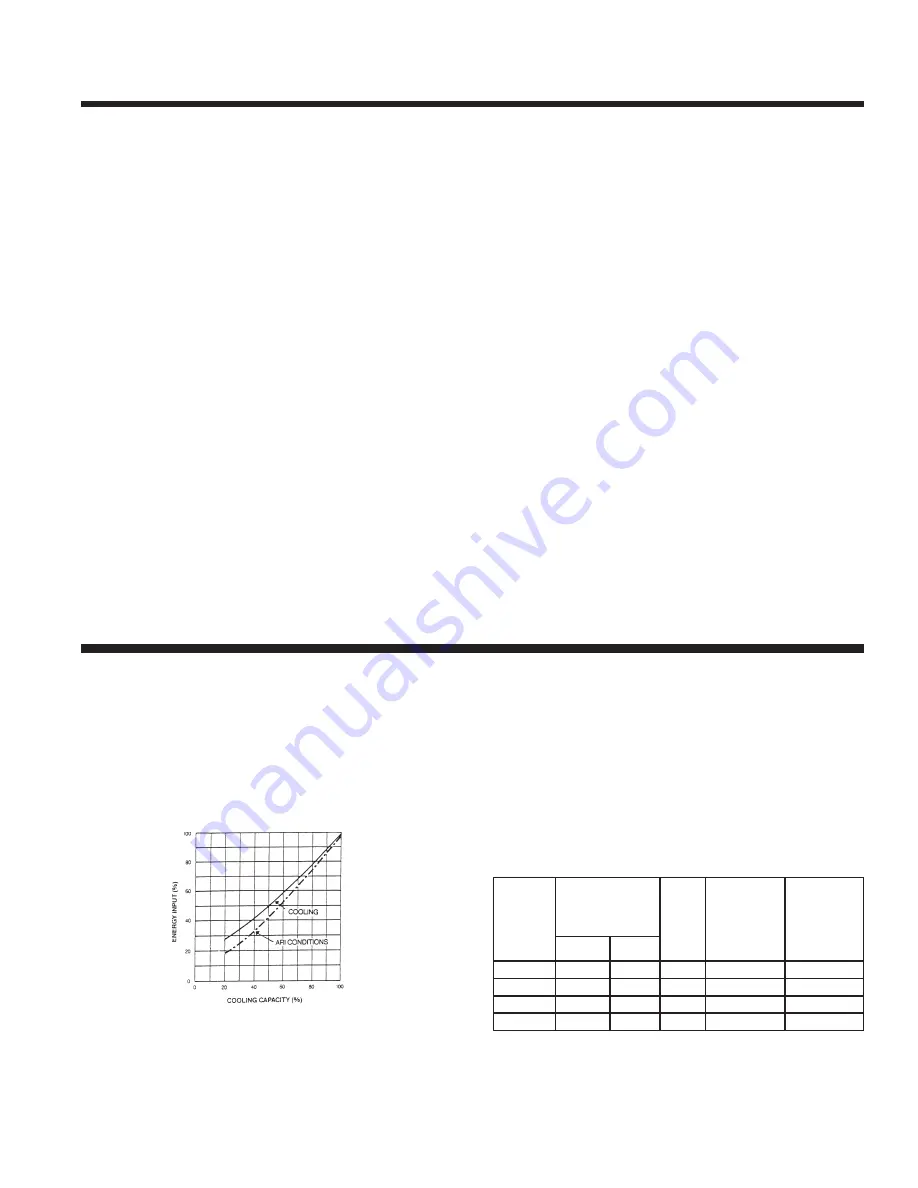

Figure 1 details the high efficiency part load performance

of the YPC Absorption Chiller. At both constant tower

water temperatures and ARI adjusted entering tower tem

-

peratures, the unique Two-Stage design delivers superior

economy at low loads. Table 1 details the YPC machine’s

superior IPLV according to ARI 560-2000.

FIGURE 1 –

ENERGY INPUT VS. OUTPUT

Shows the part load performance of the YPC Chiller. The

highest efficiency is achieved between 50 and 100 percent

chilling capacity. Valid for leaving chilled water tempera

-

ture 41°F-52°F (5.0°C-11.1°C).

IPLV (expressed as a COP) = 1.38

TABLE 1

- IPLV ANALYSIS

4. Condenser

Refrigerant from two sources – (1) liquid resulting from

the condensing of vapor produced in the First-Stage

Generator and (2) vapor produced by the Second- Stage

Generator enters the Condenser. As the liquid refrigerant

enters the low pressure of the condenser, it flashes to

vapor. The two sources of refrigerant vapor combine and

condense to liquid as they are cooled by the condenser

water. The liquid then flows down to the Evaporator.

5. Evaporator

Refrigerant liquid from the Condenser passes through a

metering valve and flows down to the Refrigerant Pump,

where it is pumped up the the top of the Evaporator. Here

the liquid is sprayed out as a fine mist over the Evapora

-

tor tubes. Due to the extreme vacuum (6 mm Hg) in the

Evaporator, some of the refrigerant liquid evaporator,

creating the refrigerant effect. (This vacuum is created by

hygroscopic action-the strong affinity LiBr has for water-in

the Absorber directly below.)

The refrigerant effect cools the returning system chilled

water in the Evaporator tubes. The refrigerant liquid/vapor

picks up the heat of the returning chilled water, cooling it

from 54°F (12.2°C) to 44°F (6.6°C). The chilled water is

then supplied back to the system.

6. Absorber

As the refrigerant liquid/vapor descends to the Absorber

from the Evaporator, a concentrated solution coming

from the Heat Exchanger is sprayed out into the flow of

descending refrigerant. The hygroscopic action between

LiBr and water, and the related changes in concentration

and temperature, result in the creation of an extreme

vacuum in the Evaporator directly above. The dissolving

of the LiBr in water gives off heat, which is removed by

condenser water entering from the cooling tower at 85°F

(29.4°C) and leaving form the Condenser at 92°F (33.3°C).

The resultant dilute LiBr solution collects in the bottom of

the Absorber, where it flows down to the Solution Pump.

The chilling cycle is now completed and begins again at

Step 1.

LOAD (%)

ENTERING CON‑

DENSER WATER

TEMP

COP

WEIGHTING

FACTOR

(FROM ARI

560‑2000)

WEIGHTED

AVERAGE

COP

°F

°C

100

85.0

29.44

1.19

0.01

0.012

75

77.5

25.28

1.32

0.42

0.554

50

70.0

21.11

1.46

0.45

0.657

25

70.0

21.11

1.3

0.12

0.156